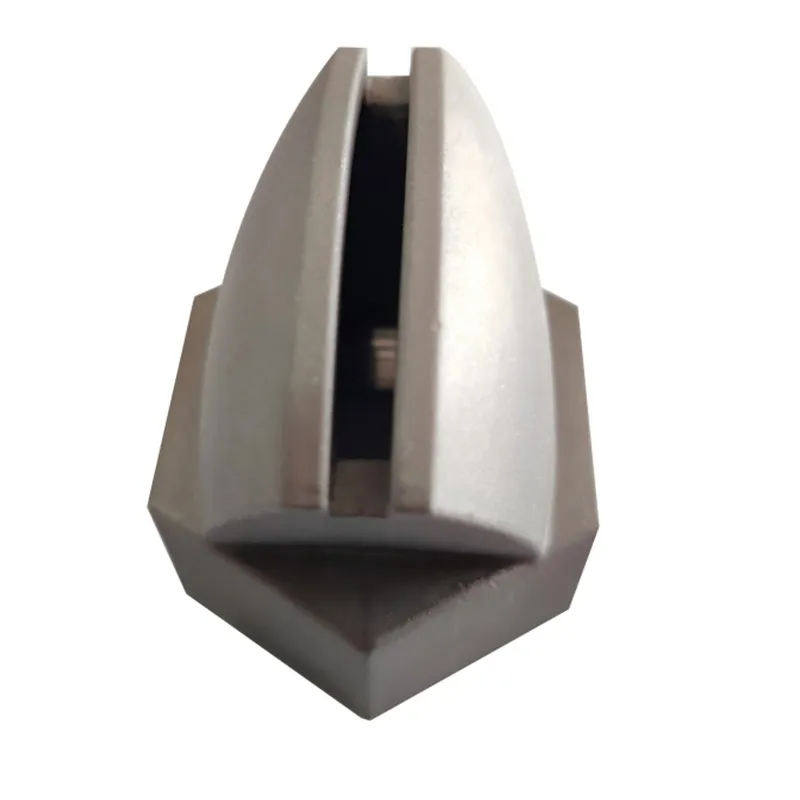

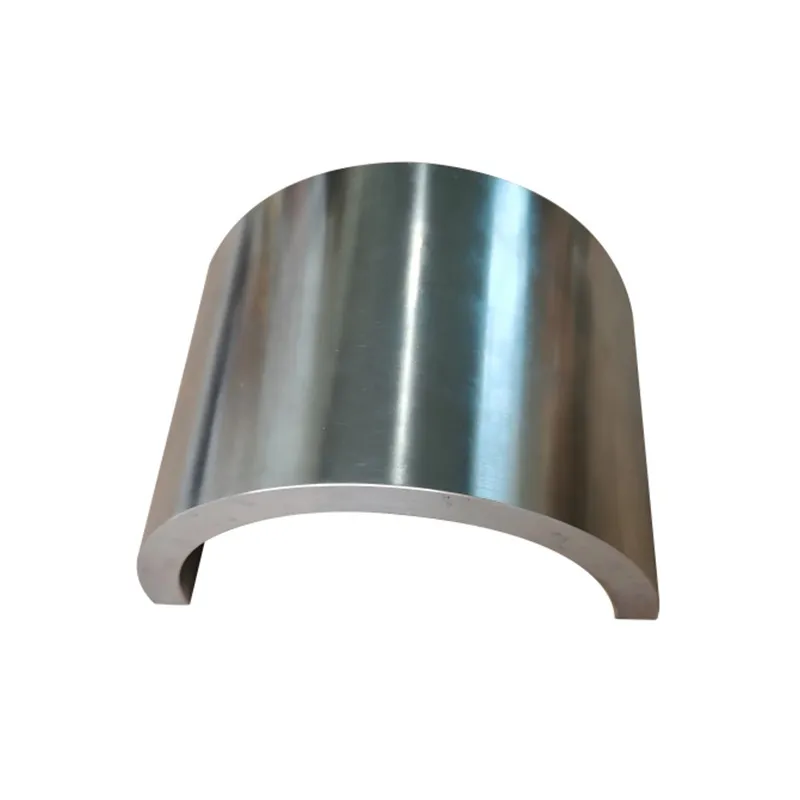

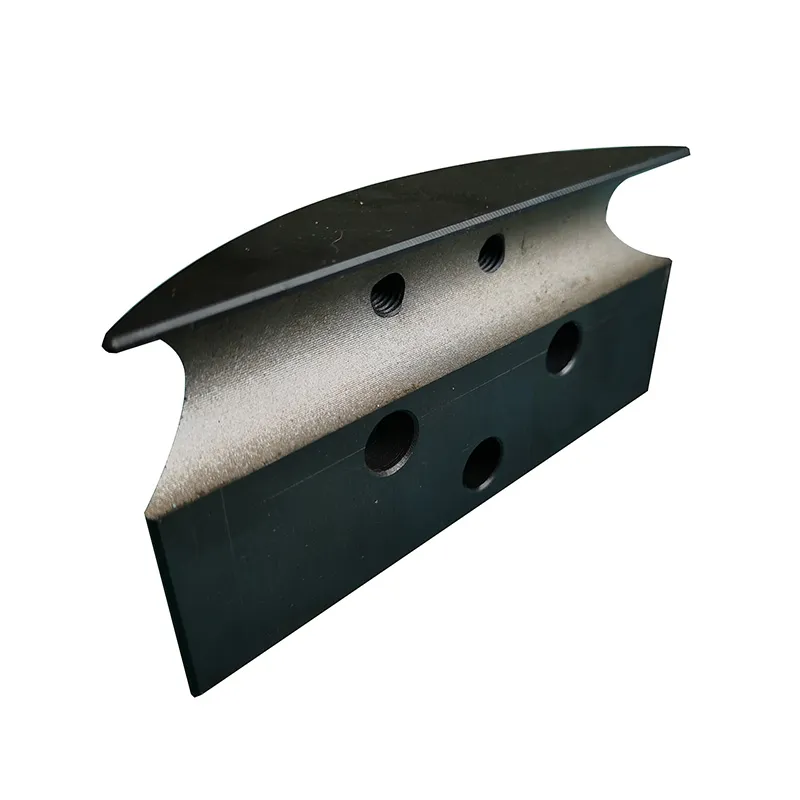

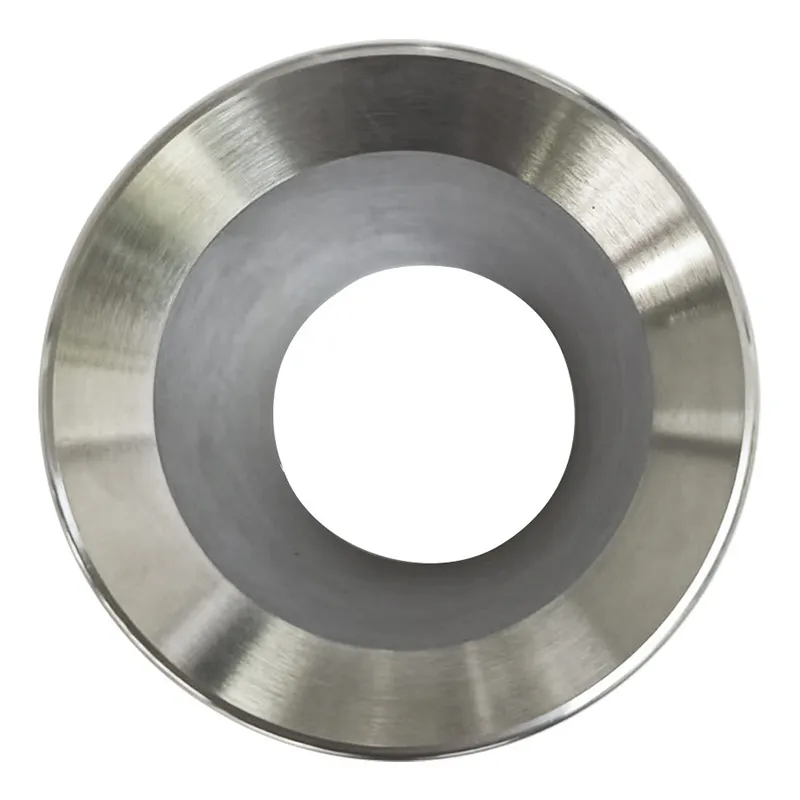

“Alloy 6” is a class of cobalt-chromium-tungsten (molybdenum) high-temperature wear-resistant alloys. These materials exhibit excellent and stable mechanical properties under extreme conditions where high temperature, wear, and corrosion coexist. The bushings we manufacture use Alloy 6 material. This material is the most commonly used Stellite material and possesses extremely excellent high-temperature resistance, corrosion resistance, and wear resistance.

Due to the excellent properties of its material, Alloy 6 bushings have many advantages in various mechanical performance aspects:

1.Excellent wear resistance and anti-galling properties: High hardness and low friction coefficient.

2.Excellent high-temperature performance: Good hardness retention at high temperatures, and wear resistance far exceeding tool steel.

3.Good corrosion resistance: Resistant to corrosion from various media, including seawater and non-oxidizing acids.

4.Excellent impact resistance: The cobalt matrix provides good toughness and can withstand thermal shock.

Material Composition and Mechanical Performance Parameters:

1.Alloy 6 Composition Table

| Chemical Composition |

| Elements |

C |

Mn |

Si |

Cr |

Ni |

Mo |

| Percentage(%) |

0.9-1.4 |

≤ 1.0 |

≤ 1.5 |

27.0-31.0 |

≤ 3.0 |

≤ 1.5 |

| Elements |

W |

Fe |

P |

S |

Co |

|

| Percentage(%) |

3.5-5.5 |

≤ 3.0 |

≤ 0.04 |

≤ 0.04 |

Bal. |

|

2.Mechanical Properties

(1).Tensile Strength (T.S): 793-896 MPa

(2).Yield Strength (Y.S): 541-662 MPa

(3).Elongation (E.L): ≤ 2%

(4).Hardness: HRC 37-45

Manufacturing Process:

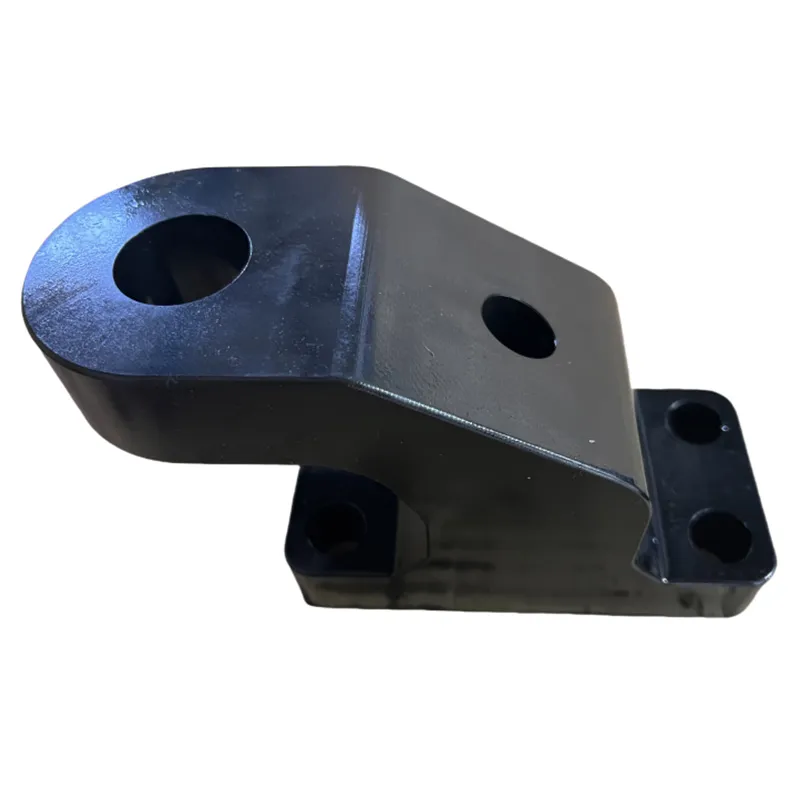

The parts are manufactured using the investment casting process, which is the most commonly used precision casting process. Because cobalt-based alloy raw materials are expensive, investment casting significantly reduces material waste by improving casting accuracy. Through extensive testing and continuous research and development, we have mastered mature special alloy casting and precision machining processes. After casting, the parts undergo precision machining to meet the accuracy requirements of the assembly surfaces. After all casting and machining processes are completed, we perform dimensional inspections to ensure that all dimensions meet specifications.

Packaging

After all tests are completed and passed, we will package and ship the products.

We will continuously track orders and follow up with customers, providing the most professional after-sales service, and constantly paying attention to customer suggestions and new needs. Customer feedback: