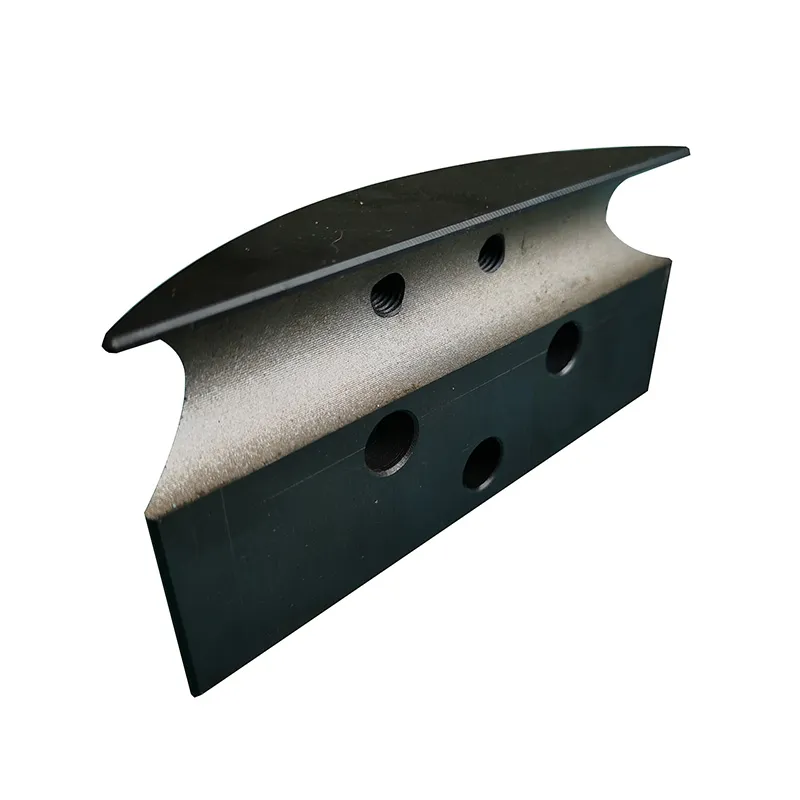

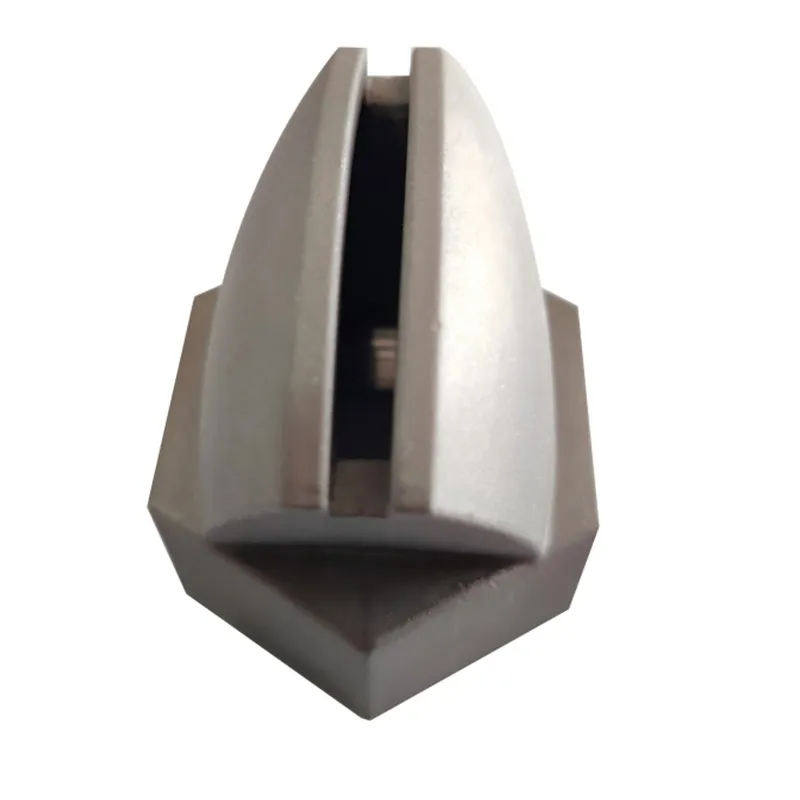

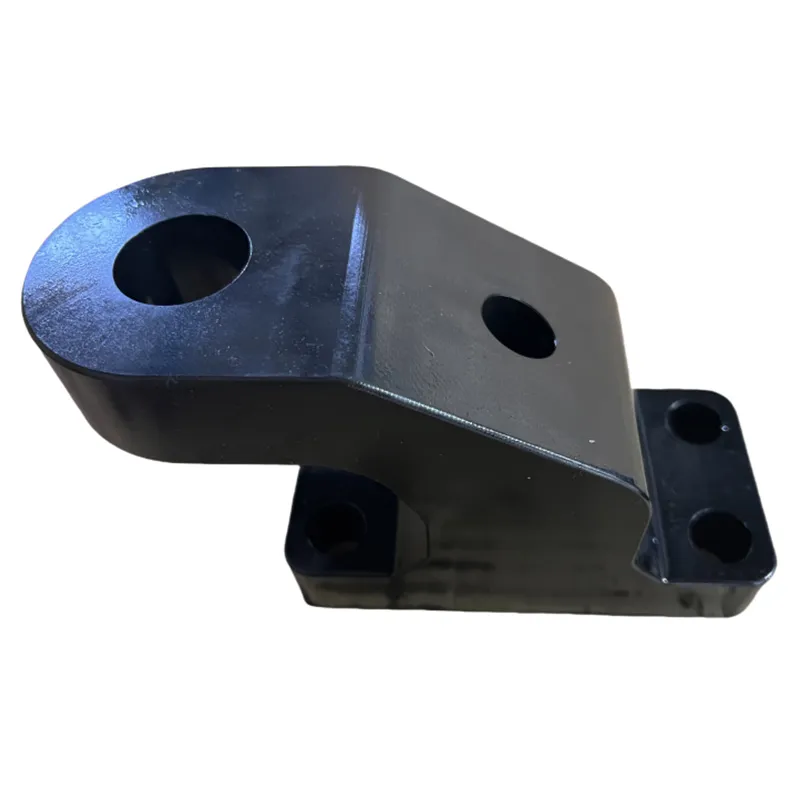

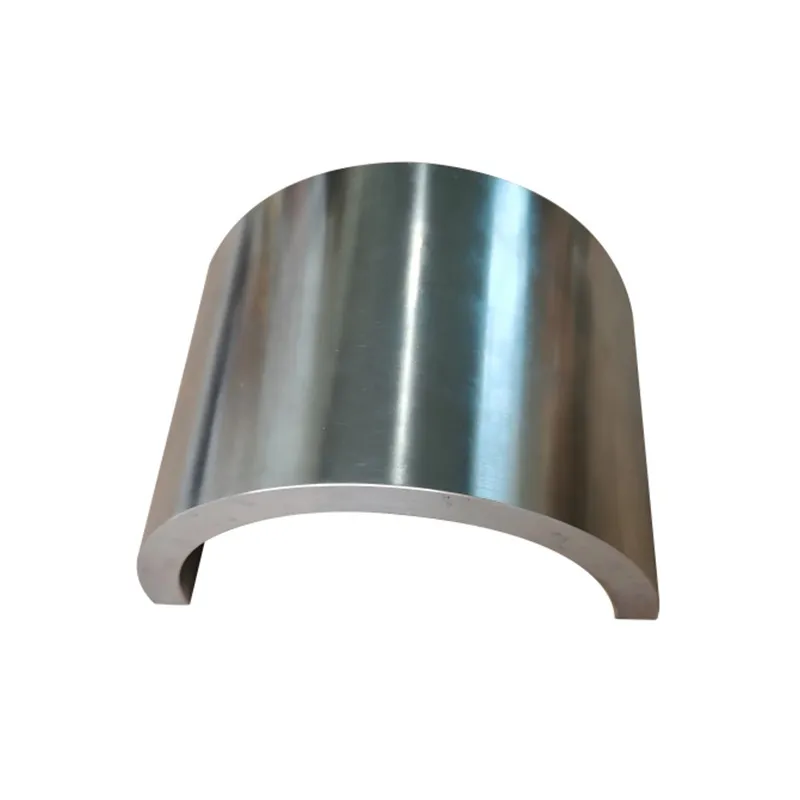

Cobalt alloy T-800 is a cobalt-based wear-resistant and corrosion-resistant alloy, renowned for its extremely high hardness and wear resistance. The bushings we manufacture for our customers are commonly used in galvanizing production lines, homogenizers, and equipment in the oil and gas exploration industries, maintaining high strength and hardness even in high-temperature environments. The material hardness reaches 54-62 HRC.

Cobalt alloy T-800 Composition Table

| Chemical Composition |

| Elements |

C |

Si |

Cr |

Mo |

Co |

| Percentage(%) |

≤ 0.5 |

≤ 3.5 |

16.5-18.5 |

27.5-31.5 |

Bal. |

Manufacturing Process:

This part is manufactured using the investment casting (lost-wax) process. Due to the high cost of cobalt-based alloy raw materials, investment casting significantly reduces material waste by improving casting precision. Through extensive testing and continuous research and development, we have mastered mature special alloy casting and precision machining processes. After casting, the parts undergo precision machining. Cobalt alloy T-800 material has low toughness and high brittleness, making it highly susceptible to cracking due to thermal stress during machining. Our long-term experience in casting and machining special alloys allows us to complete the machining process more professionally, ensuring a higher yield rate. After all casting and machining processes are completed, we conduct dimensional inspections to ensure all dimensions meet specifications. Once all inspections are passed, we package and ship the products.

We maintain order tracking and customer follow-up, providing the most professional after-sales service and constantly paying attention to customer suggestions and new needs.