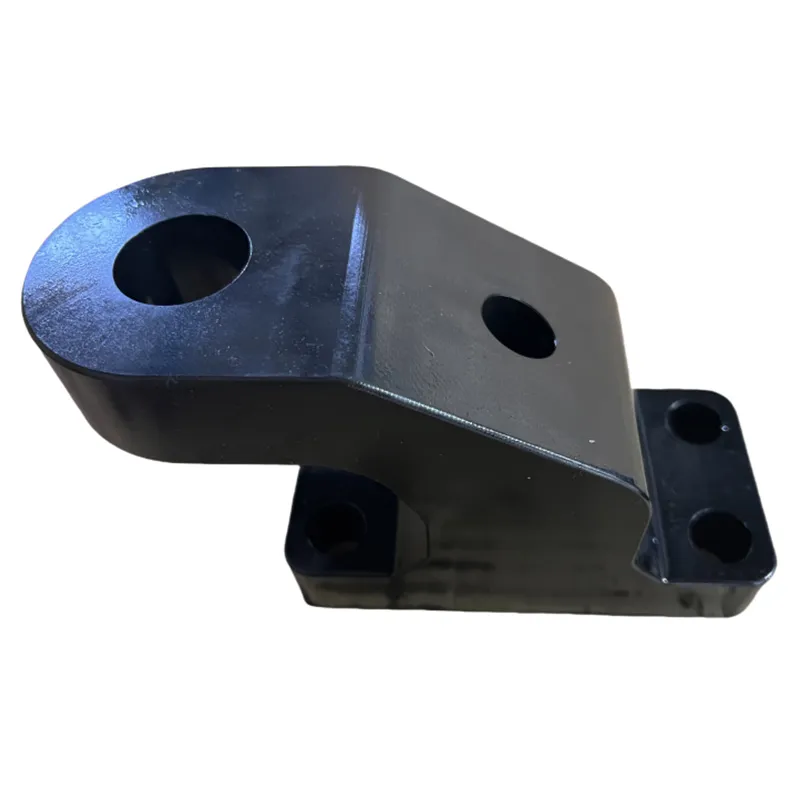

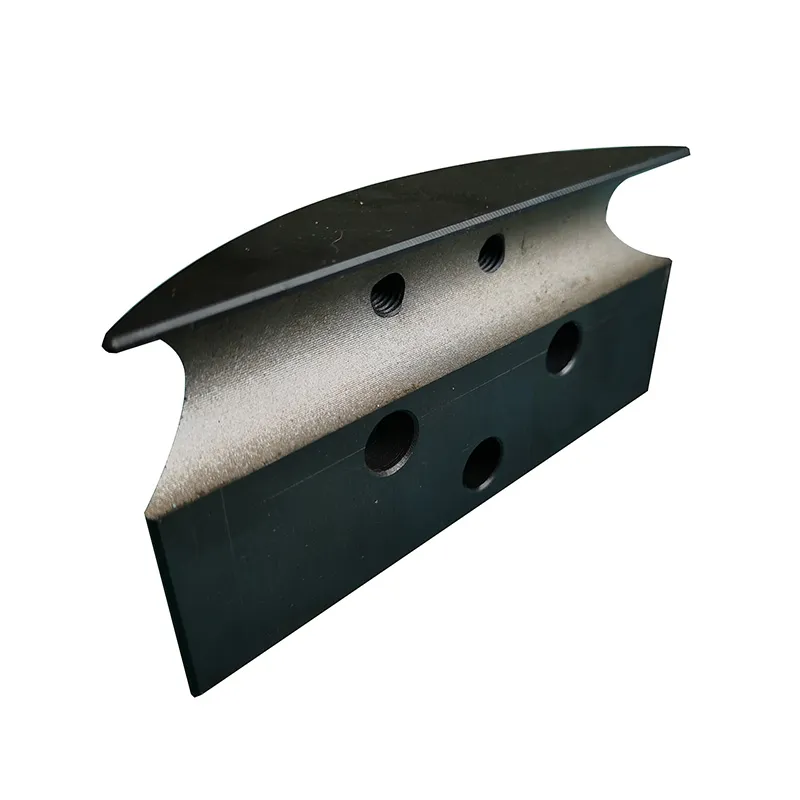

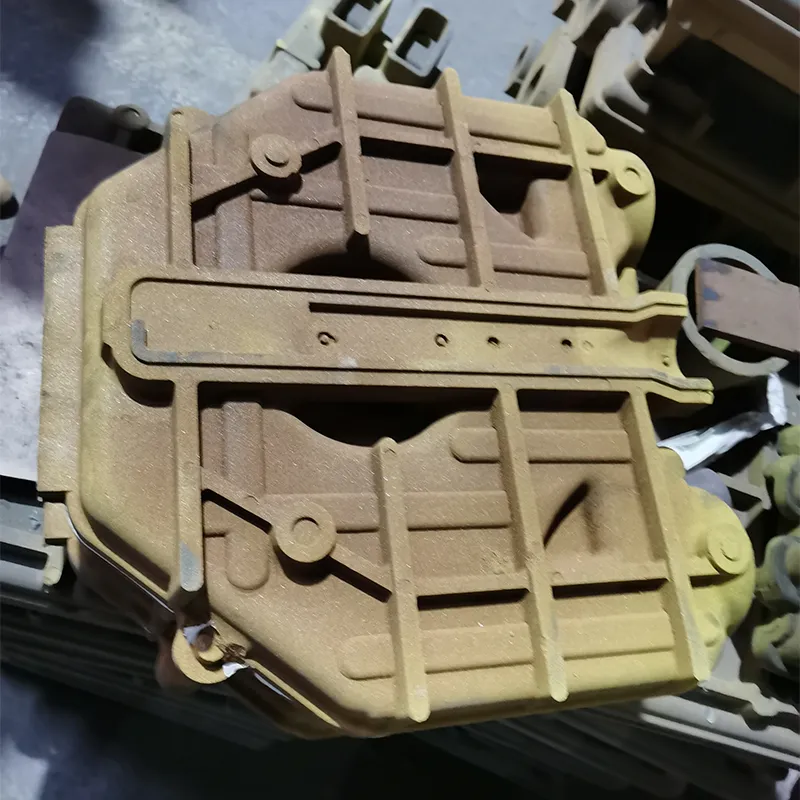

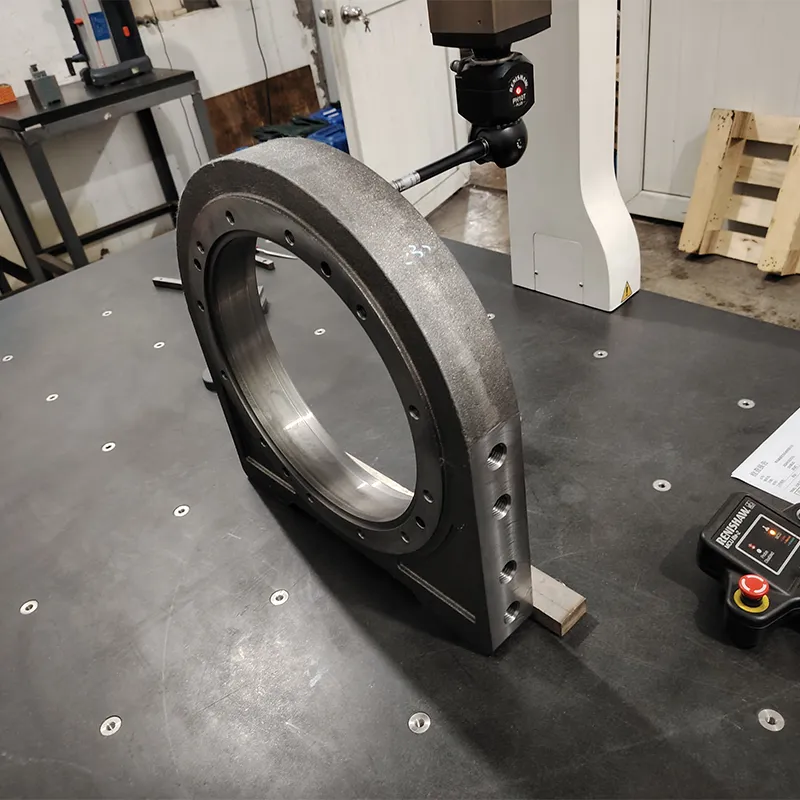

This product is a winch mounting bracket used in large engineering vehicles. The part is made of ductile iron QT400-18. This material possesses excellent toughness and ductility, good shock absorption, and wear resistance. It is a preferred material for many structural components in industrial machinery and equipment.

Material composition and mechanical property parameters:

1.QT400-18 Composition Table

| Chemical Composition |

| Elements |

C |

Si |

Mn |

P |

S |

Mg |

RE |

Fe |

| Percentage(%) |

3.6-3.8 |

2.6-2.9 |

<0.2 |

<0.08 |

<0.025 |

0.03-0.05 |

0.02-0.03 |

Bal. |

2.Mechanical properties

(1).Tensile Strength(T.S): ≥400Mpa

(2).Yield Strength(Y.S): ≥250Mpa

(3).Elongation(E.L): ≥18%

(4).HBW: 130-180

Manufacturing Process

This part is manufactured using the resin-coated sand shell gravity casting process, which improves surface roughness, ensures stable casting dimensions, significantly enhances the mechanical properties of the part, and also guarantees production efficiency.