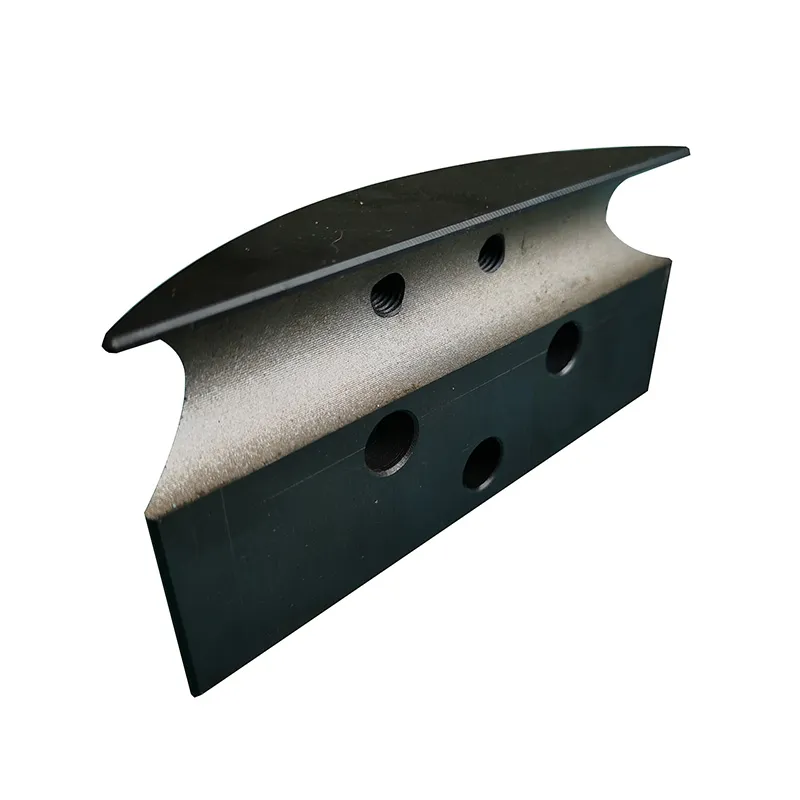

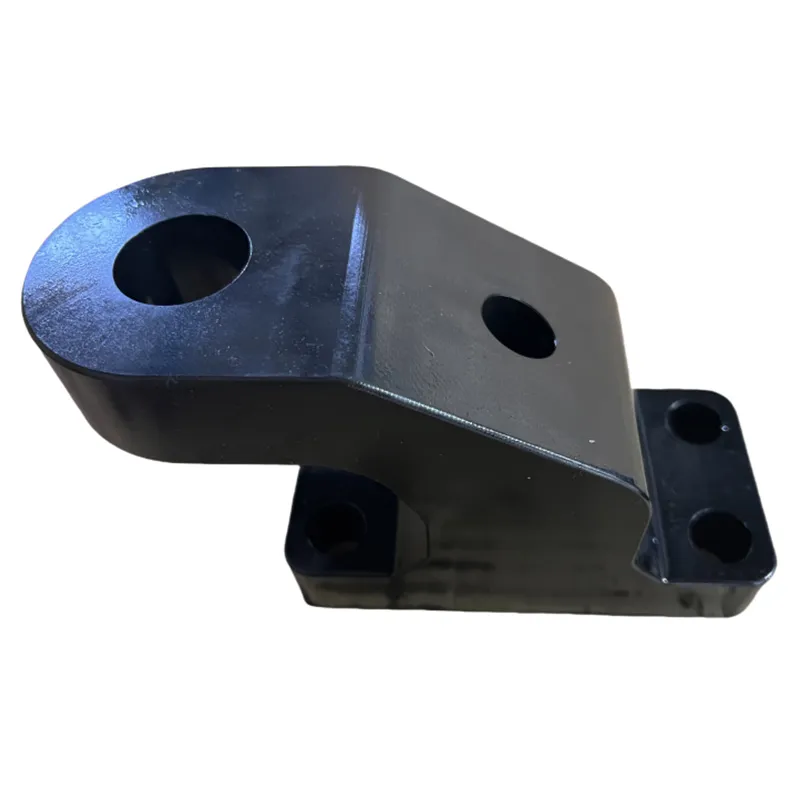

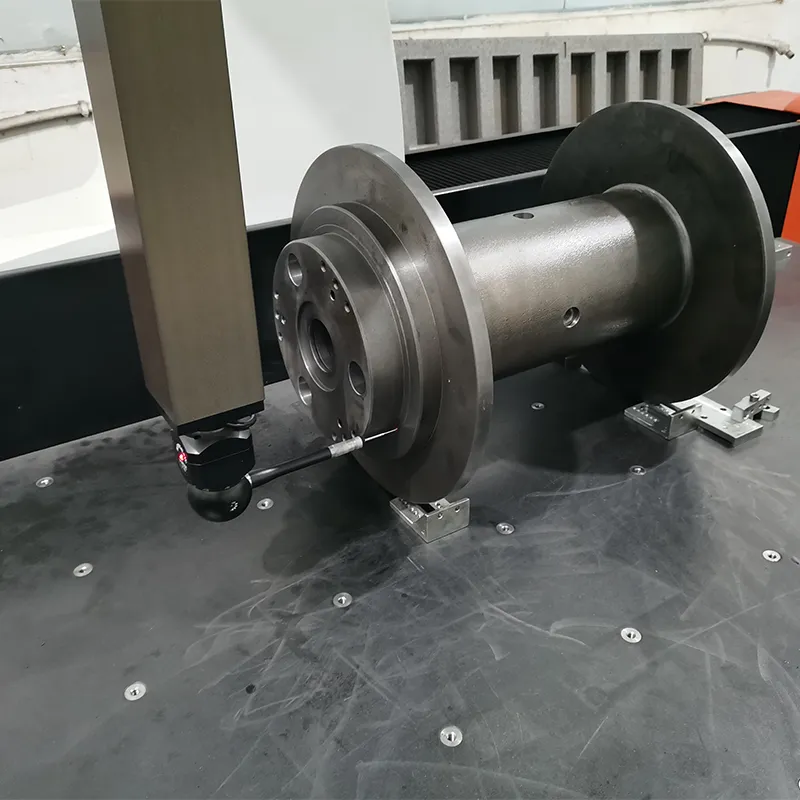

This product is used in the winch equipment assembled on large engineering vehicles. It is the winding component for the steel cable and a primary load-bearing part. The part is made of ductile iron QT400-18, which possesses excellent toughness and plasticity, good shock absorption, and wear resistance. It is the preferred material for many industrial machinery structural components.

Material Composition and Mechanical Performance Parameters:

1.QT400-18 Composition Table

| Chemical Composition |

| Elements |

C |

Si |

Mn |

P |

S |

Mg |

RE |

Fe |

| Percentage(%) |

3.6-3.8 |

2.6-2.9 |

<0.2 |

<0.08 |

<0.025 |

0.03-0.05 |

0.02-0.03 |

Bal. |

2.Mechanical properties

(1).Tensile Strength(T.S): ≥400Mpa

(2).Yield Strength(Y.S): ≥250Mpa

(3).Elongation(E.L): ≥18%

(4).HBW: 130-180

Manufacturing Process:

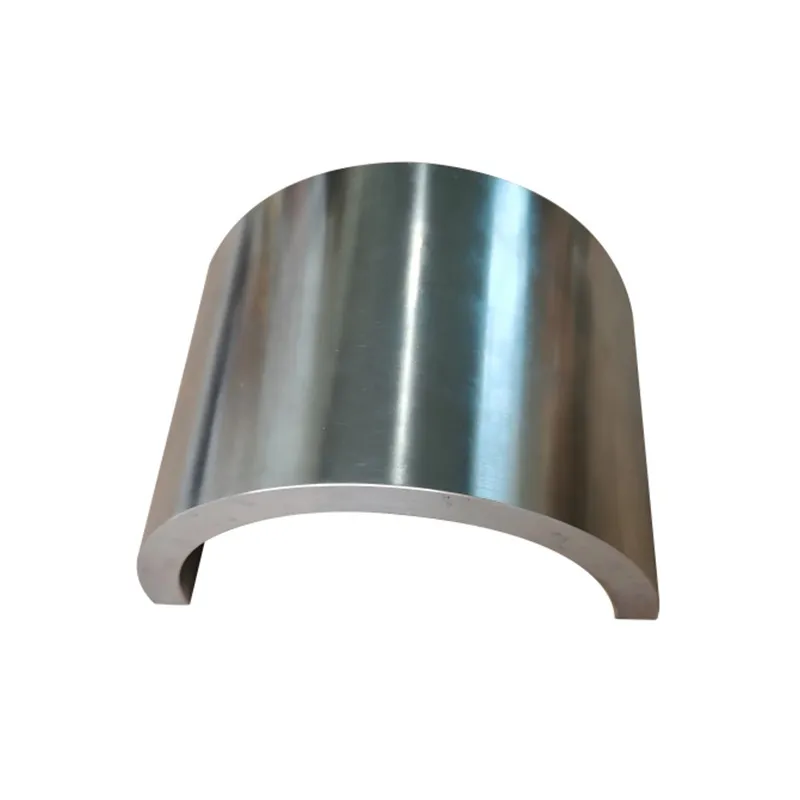

This part is manufactured using the resin-coated sand shell gravity casting process, which improves surface roughness, ensures stable casting dimensions, significantly enhances the mechanical properties of the part, and maintains high production efficiency. For such large-sized parts, internal cooling and molten metal flow design are crucial. Uneven internal cooling can easily lead to localized structural collapse and internal shrinkage porosity. Through continuous debugging and testing of the mold, we have obtained parts with a dense structure and perfect quality.