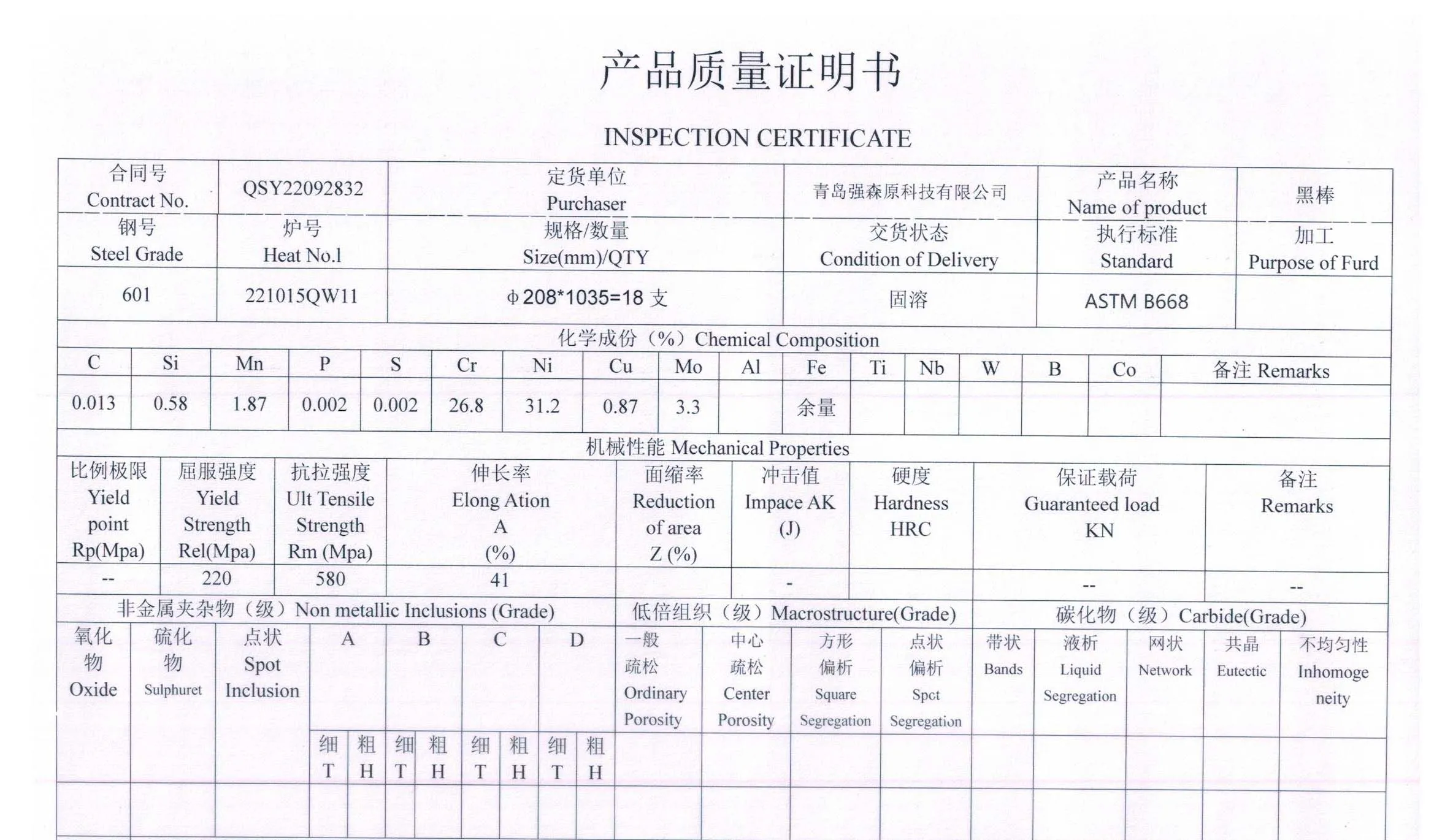

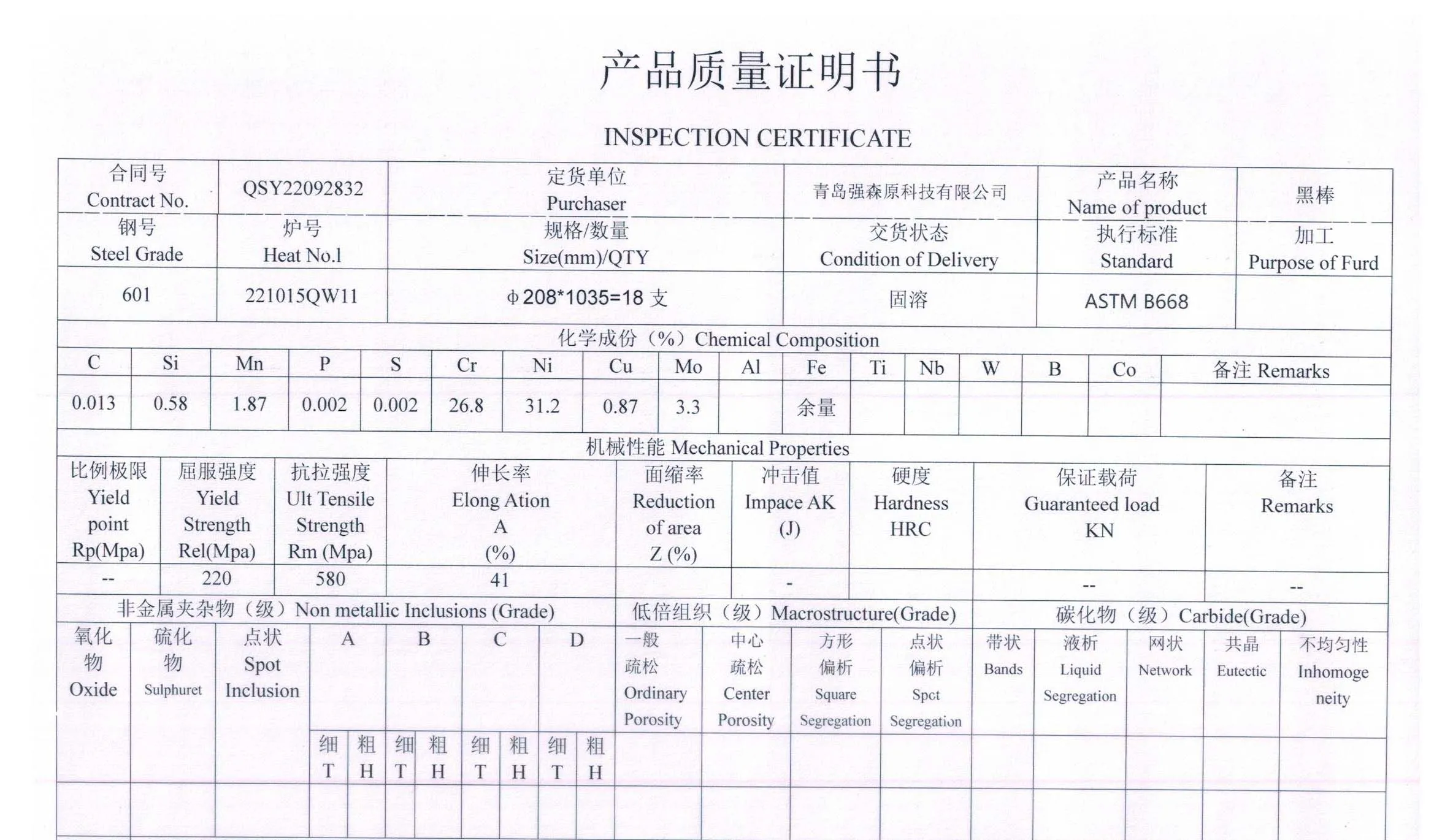

1. Khoom siv: Alloy 28 (N08028, 4563, X1NiCrMoCu31-27-4)

Chemical Component:C ≤0.02%;Si:≤1.0%;Mn:≤2.0%;P:≤0.03%;S :≤0.03%;Cr :26~28%;Ni :30~32%;Mo: 3~4%;Cu : 0.8 ~ 1.5% Fe: margin

2. Khoom Khoom:

ceev:8.1g / cm³;

melting point: 1320-1370 ℃;

lub zog ntawm extension:1650-2250MPa;

yield zog:1250-1750MPa;

Tus nqi ntawm elongation:25% -45%;

hardness:35-45 HRC

3.Main Property:

Thaum tshav kub kub cracking kuj, siab hnav tsis kam, zoo corrosion kuj, zoo liab hardness; Zoo corrosion kuj nyob rau hauv muaj zog acid ib puag ncig; Kev tiv thaiv zoo rau kev ntxhov siab corrosion tawg hauv hydrogen sulfide (H2S) thiab chloride ib puag ncig; Zoo intergranular corrosion kuj; Siab tiv taus pitting thiab crevice corrosion; Zoo weldability;

4.Alloy 28 Daim Ntawv Thov Cheeb Tsam:

Nws yog feem ntau siv rau hauv cov xov xwm hnyav corrosive xws li tshuaj lom neeg kev lag luam, thiab tuaj yeem siv rau hauv kev lag luam tshuaj, cov khoom siv tswj cov pa phem, cov roj thiab cov kav dej zoo, cov roj nuclear reprocessing, underground kev pab cuam nyob rau hauv tob sulfur gas Wells, as well as chemical processing of ntub phosphoric acid, seawater, hydrofluorinated chloride thiab organic acid ntau lawm thiab pickling khoom.

5. Cov Kev Cai Ua Haujlwm:

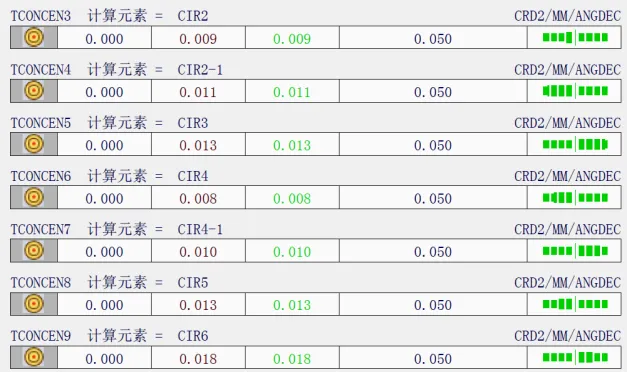

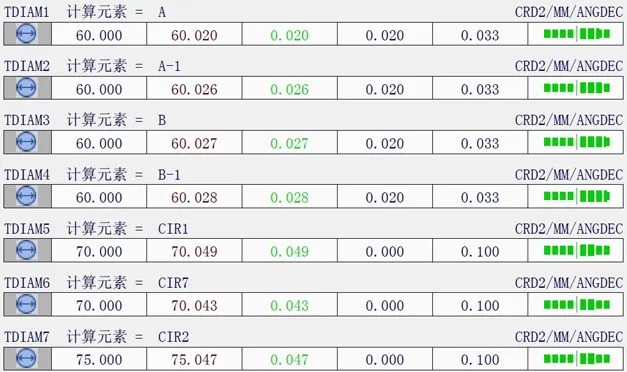

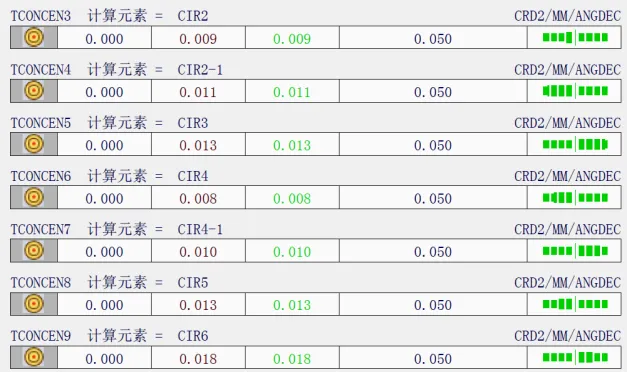

Qhov siab tshaj plaws machining raug yog 0.01mm, qhov siab tshaj plaws tiav yog RA0.6um, thiab qhov concentricity ntawm tag nrho cov txheej ncig yog nyob rau hauv 0.05mm.

6.Machining txheej txheem:

Raw khoom forging: sanicro28 yog cov khoom siv tsis zoo stainless hlau, kim, thiab cov duab loj, qhov siab tshaj plaws sab nraud yog 200MM, tsis muaj cov khoom siv ntawm qhov kev qhia tshwj xeeb no, kev siv forging los tsim cov wool embryo, vim yog qhov nyuaj ntawm cov khoom, qhov zoo tshaj plaws rau forging bar cov ntaub ntawv raws li ib tug ua blank. Lub net loj ntawm lub workpiece tom qab ua tiav yog 200 txheej kab thiab 1028 ntev, thiab cov ntaub plaub forged siv yog 210 txheej kab thiab 1100 ntev.

Kev ua haujlwm nyuaj:Vim hais tias cov khoom muaj cov ntsiab lus siab ntawm chromium thiab muaj ib feem ntawm molybdenum, uas ua rau lub siab hardness ntawm lub workpiece, cov ntsiab lus ntawm npib tsib xee kuj siab, cov khoom toughness yog siab, cov txheej txheem yog ib qho nyuaj, thiab nws yog ib qho yooj yim mus tshwm chip breaking thiab sticking riam thiab resonance teeb meem. ua hauj lwm efficiency thiab sticking cuab tam, thiab cov teeb meem resonance ntawm workpiece thiab tig lub cuab tam.Siv ib tug tshwj xeeb programming txoj kev, kev siv ntawm cyclic fluctuations nyob rau hauv workpiece ceev thiab pub ceev, qhov kawg zoo meej tov rau lub resonance teeb meem.

Polishing nyuaj: Lub workpiece viscosity loj, ua rau cov khib nyiab loj ntawm cov khoom sib tsoo ntawm lub log sib tsoo, thiab nws tsis tuaj yeem zom ib txwm. Thaum kawg, cov txheej txheem tshuab dhos ua tiav yog siv los ua kom tiav qhov yuav tsum tau ua kom tiav RA0.6um.

7. Cov ntaub ntawv qhia

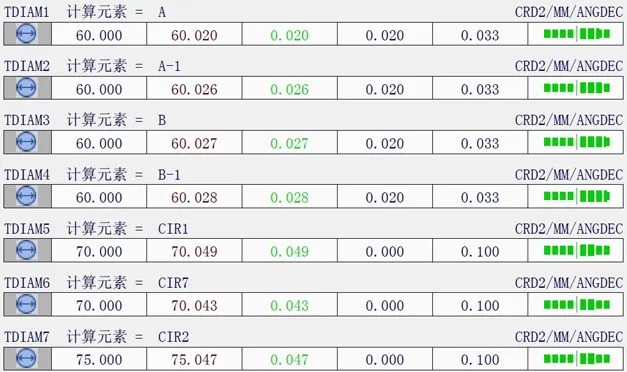

8.Kev ntsuas ntsuas (CMM ntsuas)