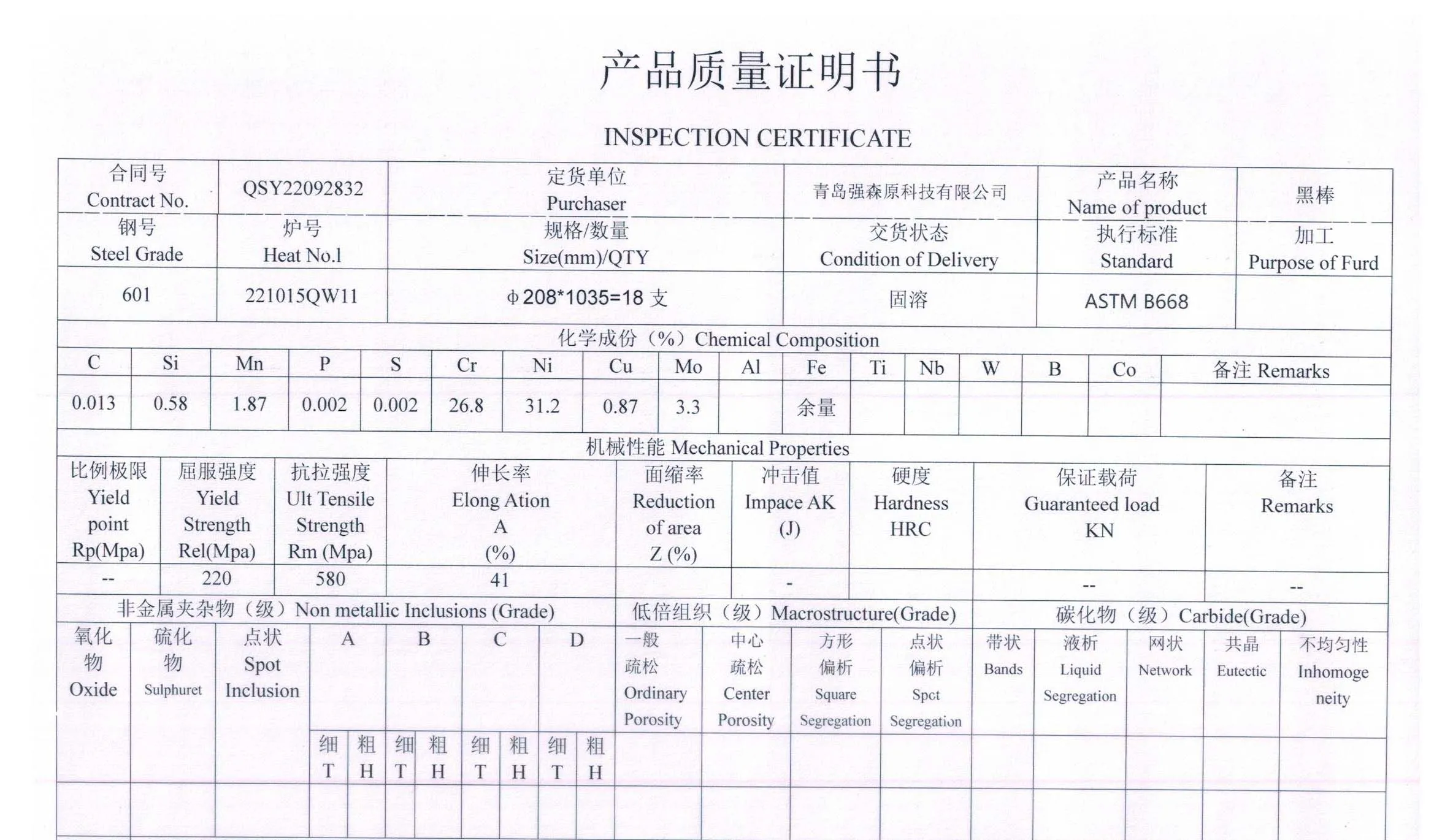

1.Material: Alloy 28(N08028,4563,X1NiCrMoCu31-27-4)

Chemical Component:C ≤0.02%;Si:≤1.0%;Mn:≤2.0%;P:≤0.03%;S :≤0.03%;Cr :26~28%;Ni :30~32%;Mo: 3~4%;Cu : 0.8~1.5% ;Fe:margin

2.Material Property:

density:8.1g/cm³;

melting point: 1320-1370℃;

strength of extension:1650-2250MPa;

yield strength:1250-1750MPa;

rate of elongation:25%-45%;

hardness:35-45HRC

3.Main Property:

Heat cracking resistance, high wear resistance, good corrosion resistance, good red hardness; Good corrosion resistance in strong acid environment; Good resistance to stress corrosion cracking in hydrogen sulfide (H2S) and chloride environments; Good intergranular corrosion resistance; High resistance to pitting and crevice corrosion; Good weldability;

4.Alloy 28 Application Areas:

It is often used in harsh corrosive media such as chemical industry, and can be used in chemical processing, pollution control equipment, oil and gas well pipelines, nuclear fuel reprocessing, underground operation services in deep sulfur gas Wells, as well as chemical processing of wet phosphoric acid, seawater, hydrofluorinated chloride and organic acid production and pickling equipment.

5.Processing Requirements:

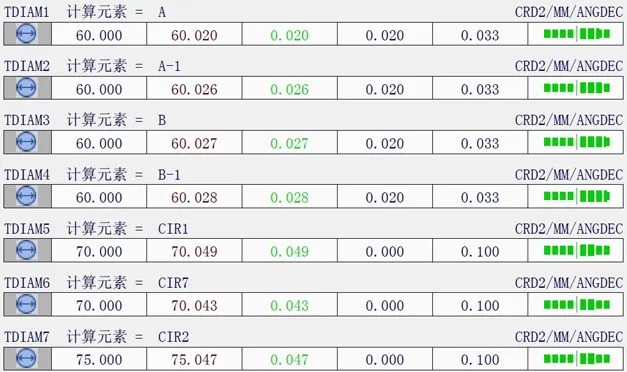

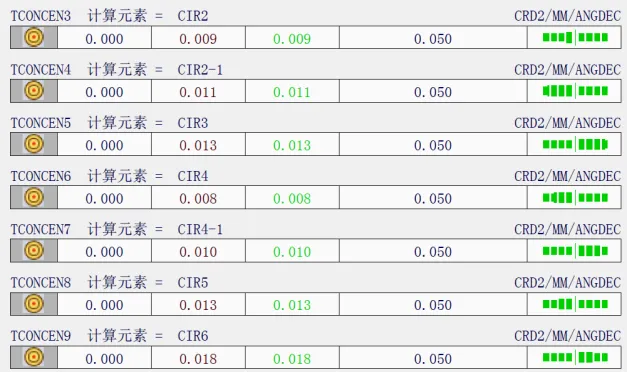

The highest machining accuracy is 0.01mm, the highest finish is RA0.6um, and the concentricity of all outer circular surfaces is within 0.05mm.

6.Machining Process:

Raw material forging:sanicro28 is an unconventional stainless steel material, expensive, and large shape, the maximum outside diameter is 200MM, no bar material of this specification, the use of forging to produce wool embryo, due to the high hardness of the material, the most suitable for forging bar material as a processing blank. The net size of the workpiece after processing is 200 outer diameter and 1028 length, and the forged wool used is 210 outer diameter and 1100 length.

Processing difficulty:Because the material has a high content of chromium and contains part of molybdenum, resulting in a high hardness of the workpiece, the content of nickel is also high, the material toughness is high, the processing is difficult, and it is easy to appear chip breaking and sticking knife and resonance problems.After the process development, the high hardness alloy blade is used, and the chip discharge groove is reserved on the blade, which solves the problem of processing efficiency and sticking tool, and the resonance problem of the workpiece and the turning tool.Using a special programming method, the use of cyclic fluctuations in workpiece speed and feed speed, the final perfect solution to the resonance problem.

Polishing difficulty:The workpiece viscosity is large, resulting in serious debris of the adhesion material of the grinding wheel, and it is impossible to grind normally. Finally, the lathe finishing scheme is used to complete the requirement of surface finish RA0.6um.

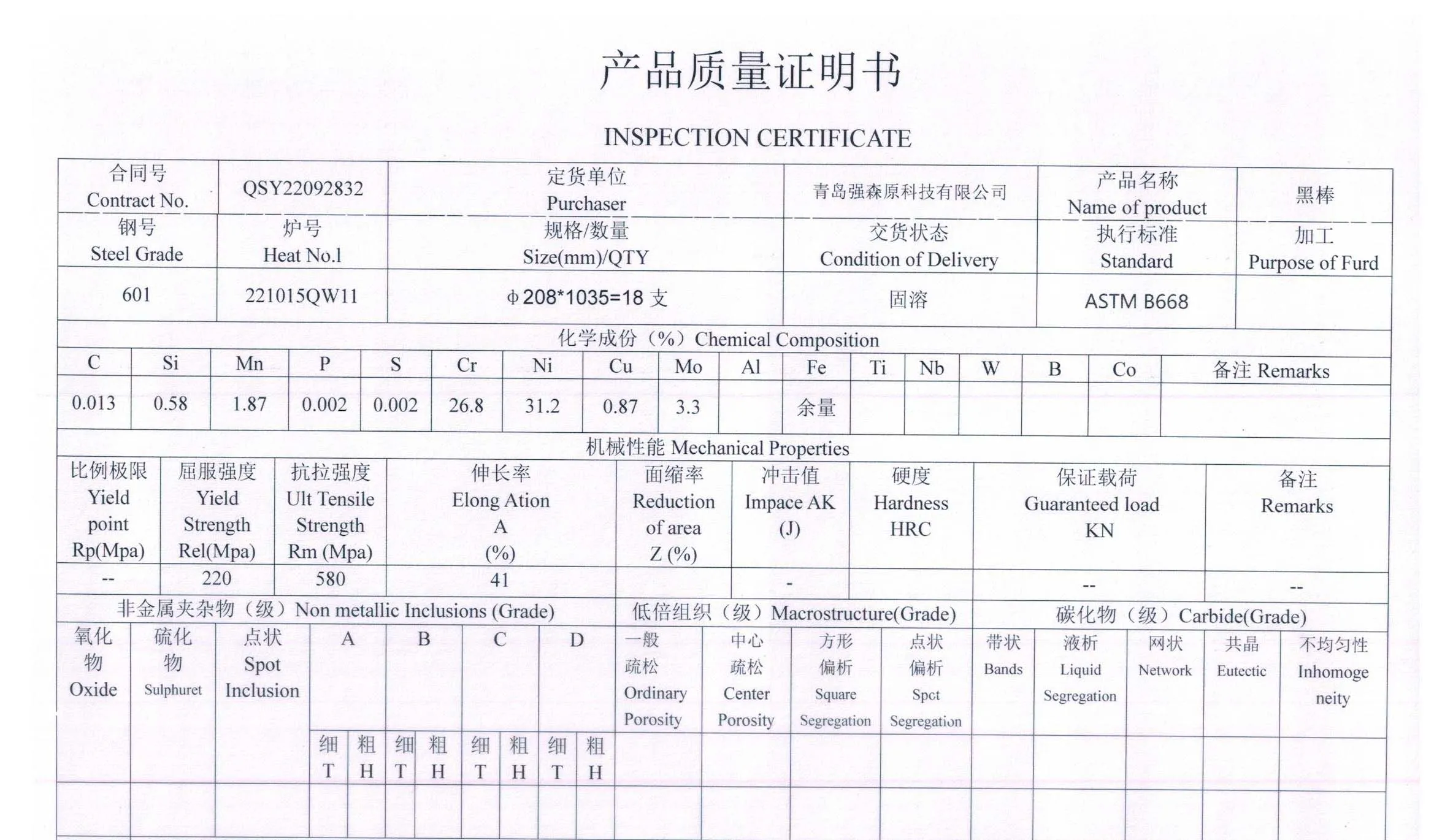

7.Material Report

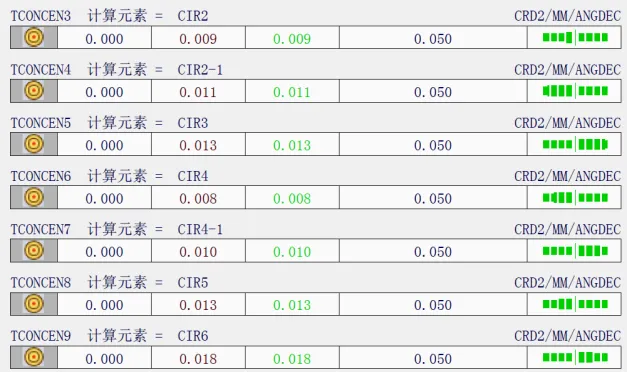

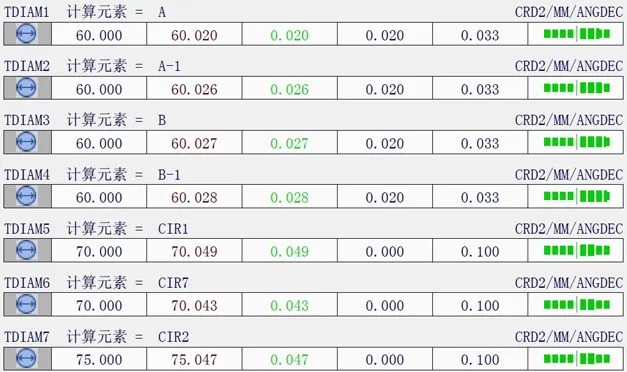

8.Coordinate Measuring(CMM measure)