1.Material: Alloy 28 (N08028, 4563, X1NiCrMoCu31-27-4)

Ihe mejupụtara kemịkalụ:C ≤0.02%;Si:≤1.0%;Mn:≤2.0%;P:≤0.03%;S 3% ;Cu: 0.8 ~ 1.5% ;fe: oke

2. Ihe onwunwe:

njupụta:8.1g/cm³;

ebe mgbaze: 1320-1370 ℃;

ike ndọtị:1650-2250MPa;

nye ike:1250-1750MPa;

ọnụego elongation:25% -45%;

isi ike:35-45HRC

3.Main Property:

Okpomọkụ na-agbawa agbawa, akwa mkpuchi mkpuchi, ezigbo nguzogide corrosion, ezigbo isi ike na-acha uhie uhie; Ezigbo nguzogide corrosion na gburugburu acid siri ike; Ezigbo iguzogide nrụgide corrosion mgbawa na hydrogen sulfide (H2S) na gburugburu chloride; Ezigbo nguzogide corrosion intergranular; Nnukwu iguzogide pitting na crevice corrosion; Ezi weldability;

4.Alloy 28 Ngwa Mpaghara:

A na-ejikarị ya eme ihe na mgbasa ozi na-emebi emebi dị ka ụlọ ọrụ kemịkalụ, enwere ike iji ya na nhazi kemịkalụ, akụrụngwa njikwa mmetọ, mmanụ na gas nke ọma pipeline, nrụpụta mmanụ nuklia, ọrụ ọrụ n'okpuru ala na sọlfọ gas Wells, yana nhazi kemịkalụ nke mmiri phosphoric acid, mmiri mmiri, hydrofluorinated chloride na organic acid mmepụta na akụrụngwa pickling.

5.Nhazi chọrọ:

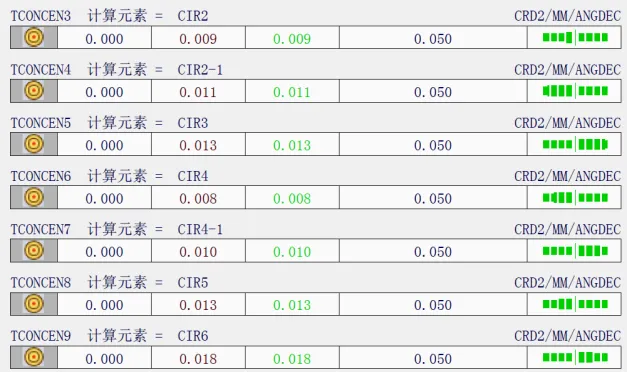

Nke kachasi n'ichepụta ziri ezi bụ 0.01mm, kasị elu imecha bụ RA0.6um, na concentricity nke niile mpụta okirikiri na-ebupụta bụ n'ime 0.05mm.

6.Machining Usoro:

Ngwongwo ihe eji eme ihe: sanicro28 bụ ihe anaghị agba nchara igwe anaghị agba nchara, dị oke ọnụ, na nnukwu udi, oke dị n'èzí bụ 200MM, enweghị ihe mgbochi nke nkọwapụta a, ojiji nke forging na-emepụta embrayo ajị anụ, n'ihi ịdị elu nke ihe ahụ, nke kachasị mma maka imepụta ihe mgbochi dị ka oghere nhazi. The net size nke workpiece mgbe nhazi bụ 200 elu dayameta na 1028 ogologo, na esorowo ajị anụ eji bụ 210 elu dayameta na 1100 ogologo.

Isi ike nhazi:N'ihi na ihe nwere nnukwu ọdịnaya nke chromium na nwere akụkụ nke molybdenum, na-eme ka a elu hardness nke workpiece, ọdịnaya nke nickel dịkwa elu, ihe siri ike dị elu, nhazi bụ siri ike, na ọ dị mfe ịpụta mgbawa na-agbaji na ịrapara mma na resonance. arụmọrụ na ịrapara ngwá ọrụ, na resonance nsogbu nke workpiece na mbịne ngwá ọrụ. Iji a pụrụ iche mmemme usoro, ojiji nke cyclic mgbanwe na workpiece ọsọ na ndepụta ọsọ, ikpeazụ zuru okè ngwọta na resonance nsogbu.

Ihe isi ike na-egbuke egbuke: viscosity workpiece buru ibu, na-ebute mkpọmkpọ ebe nke ihe adhesion nke wiil egweri, na ọ gaghị ekwe omume ịkwanye nke ọma. N'ikpeazụ, a na-eji atụmatụ imecha lathe emecha ihe achọrọ maka imecha elu RA0.6um.

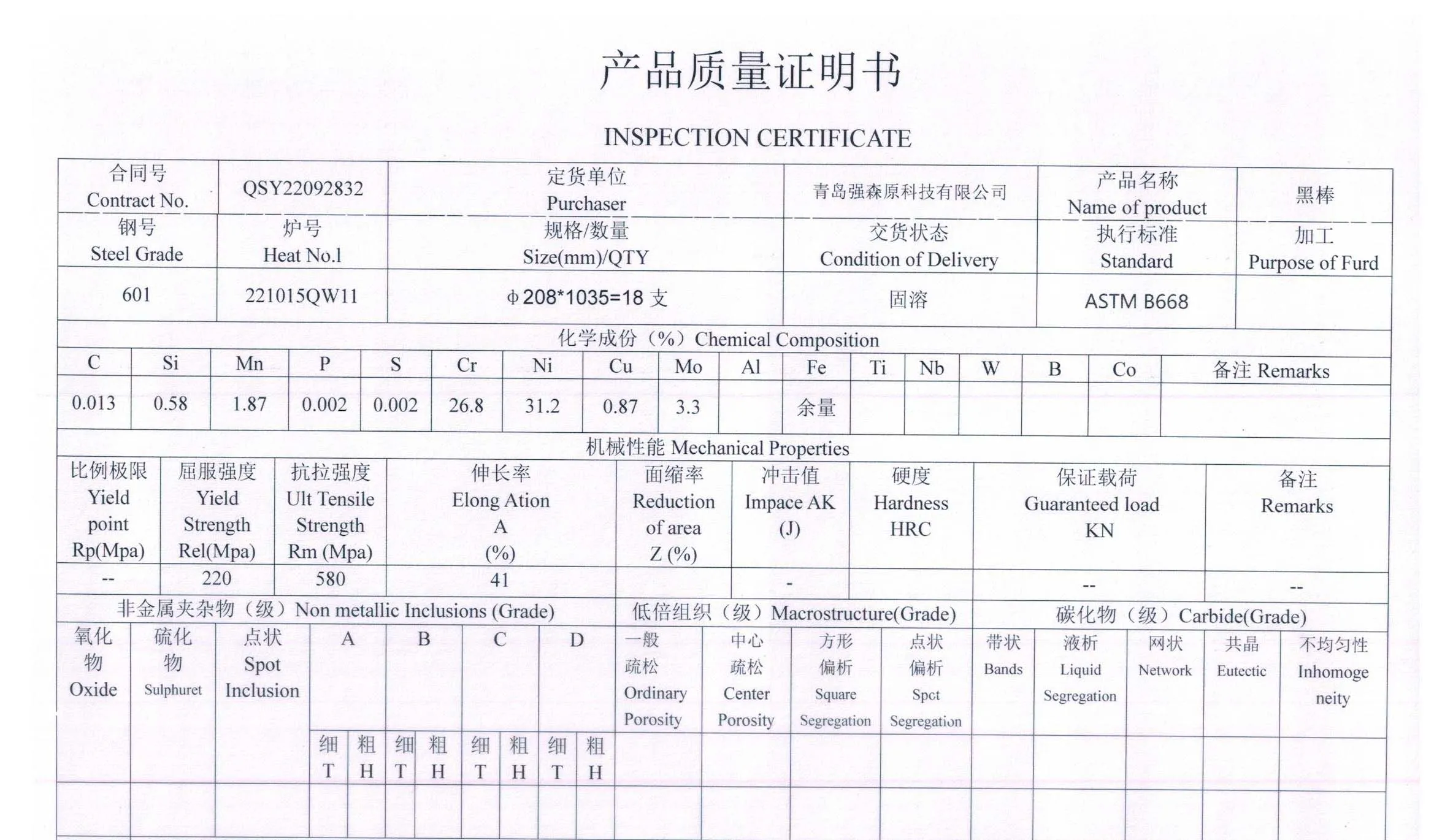

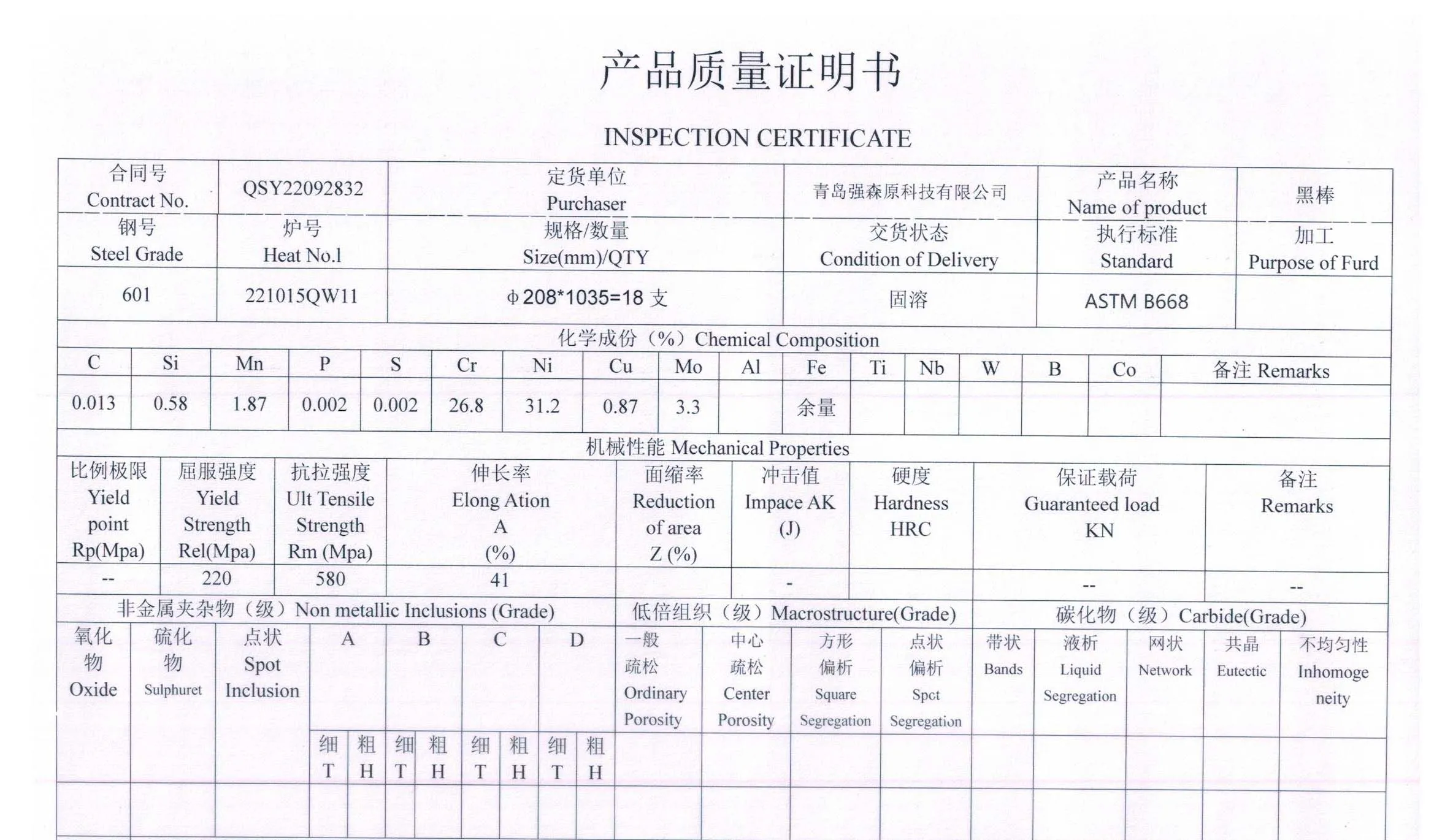

7.Material Report

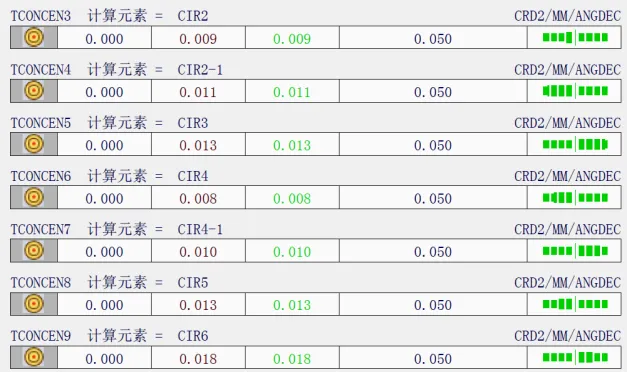

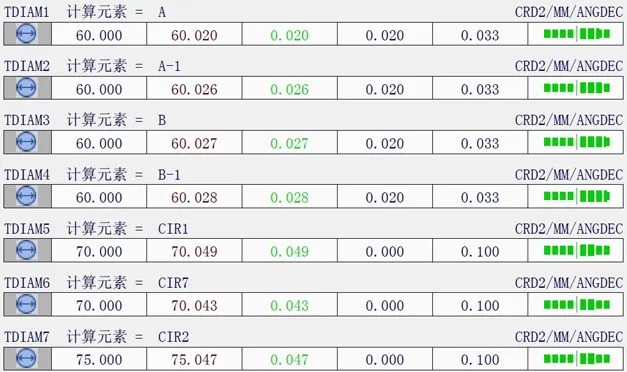

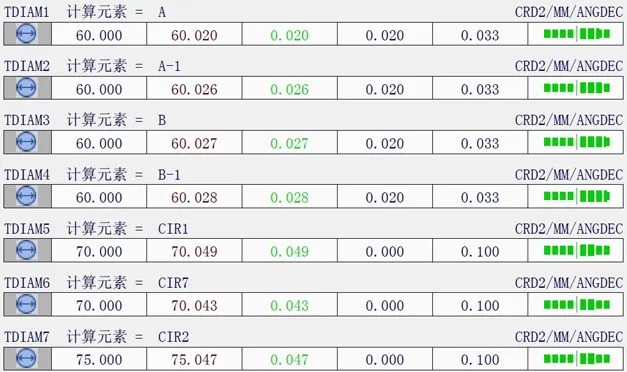

8.Coordinate Measuring(CMM nha)