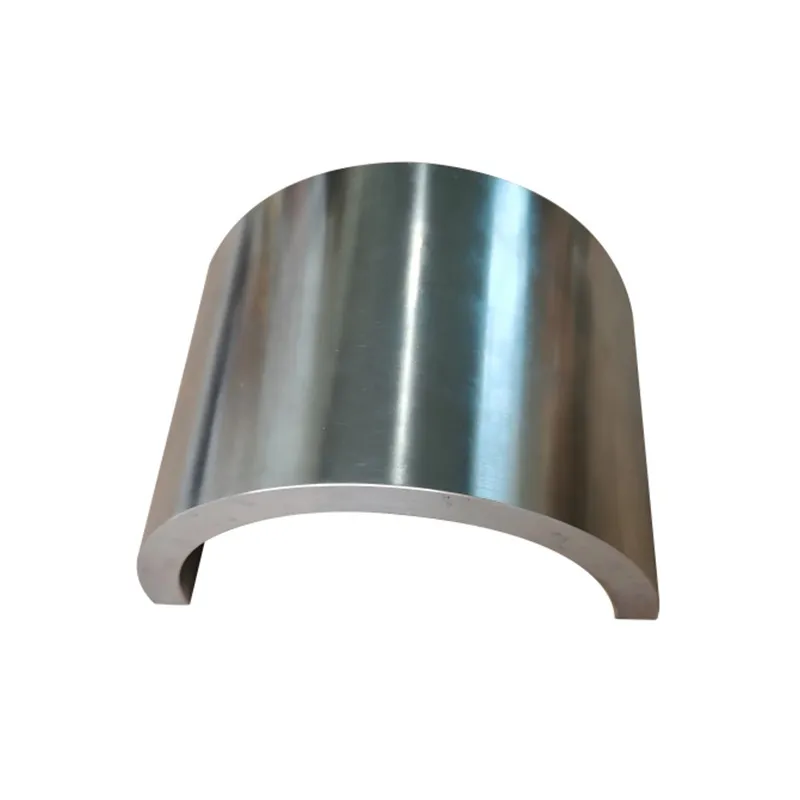

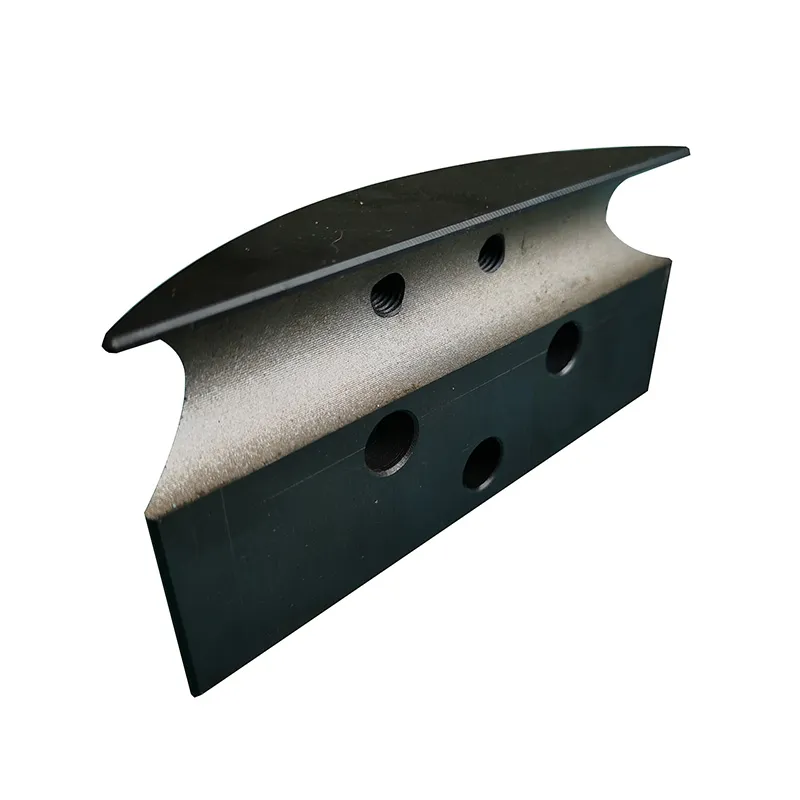

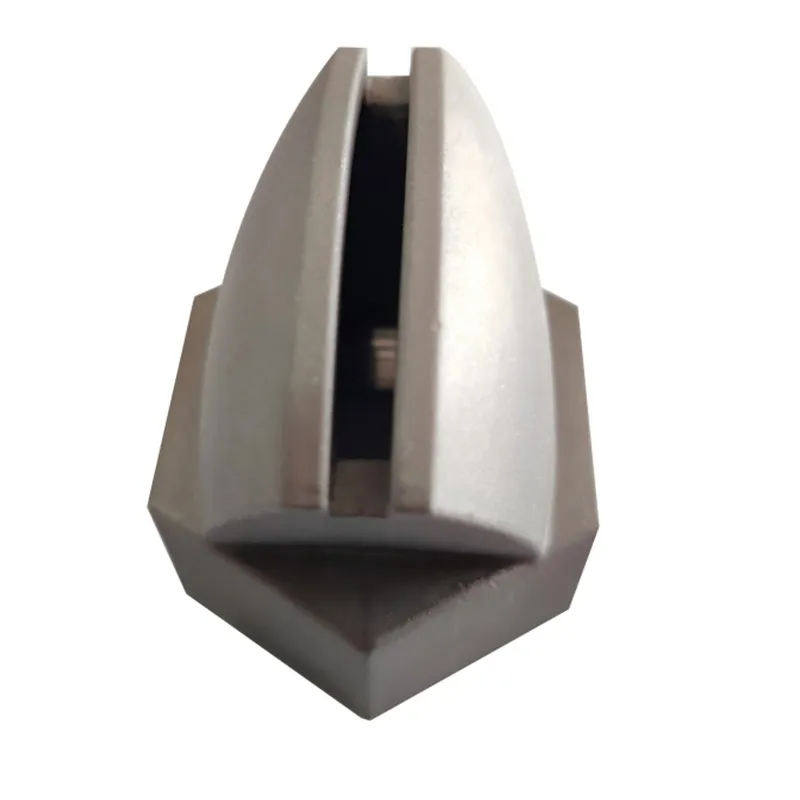

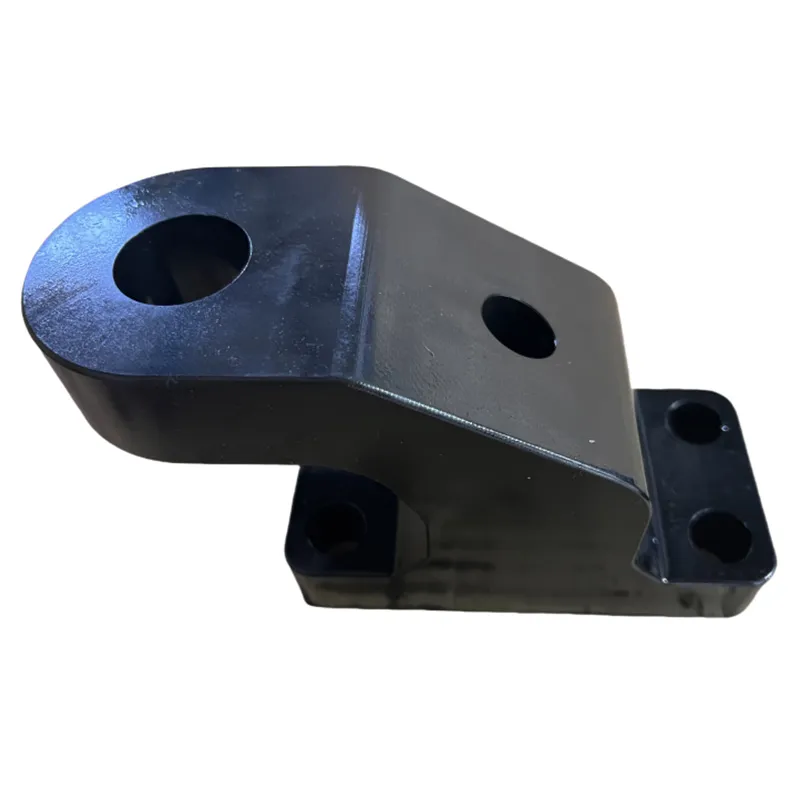

A lifting pulley is a mechanical device used for high-altitude work or heavy lifting, which lifts or moves heavy objects by changing the direction or magnitude of the force. We manufactured lifting pulleys for a client's engineering vehicles. The material of this pulley part is 30CrMnSiA (30ХГСА). This material has excellent tensile strength and yield strength. We also enhanced the strength and toughness of the part through heat treatment.

Material Composition and Mechanical Properties Parameters:

1.30CrMnSiA Structural Steel Composition Table

| Chemical Composition |

| Elements |

C |

Si |

Cr |

Mn |

Ni |

P |

S |

Gu |

Fe |

| Percentage(%) |

0.28-0.34 |

0.9-1.2 |

0.8-1.1 |

0.8-1.1 |

≤ 0.30 |

≤ 0.025 |

≤ 0.025 |

≤ 0.30 |

Bal. |

2.Mechanical Properties

(1).Tensile Strength (σb): ≥ 1100 MPa

(2).Yield Strength (σs): ≥ 835 MPa

(3).Elongation (δ5): ≥ 10%

(4).Impact Energy (Akv): ≥ 39-50 J

(5).Brinell Hardness: ≤ 229 HB (Annealed state)

Manufacturing Process:

The parts are manufactured using the lost-wax precision casting process, which can meet the casting requirements of larger-sized parts and better guarantee the casting accuracy. After casting, the parts undergo heat treatment and tempering to meet the hardness requirements, achieving a hardness of 28-30 HRC after heat treatment. The parts are then precision machined to meet the accuracy requirements of the assembly surfaces. Finally, the parts are galvanized or powder coated.