The N08028 stainless steel shafts we manufacture for our customers are used in galvanizing production line equipment. N08028 (also known as Alloy 28 or Sanicro 28) is a highly alloyed super austenitic stainless steel or iron-nickel-based corrosion-resistant alloy, specifically designed to withstand harsh acidic and chloride-containing environments. It is widely used in chemical, oil and gas, and environmental protection industries.

Material Composition and Mechanical Properties Parameters:

1.N08028 Stainless Steel Composition Table

| Chemical Composition |

| Elements |

C |

Ni |

Cr |

Mo |

Cu |

Fe |

| Percentage(%) |

≤ 0.03 |

30.0-34.0 |

26.0-28.0 |

3.0-4.0 |

0.6-1.4 |

Bal. |

2.Mechanical Properties

(1).Tensile Strength (T.S): ≥500 MPa

(2).Yield Strength (Y.S): ≥215-240 MPa

(3).Elongation (E.L): ≥35-40%

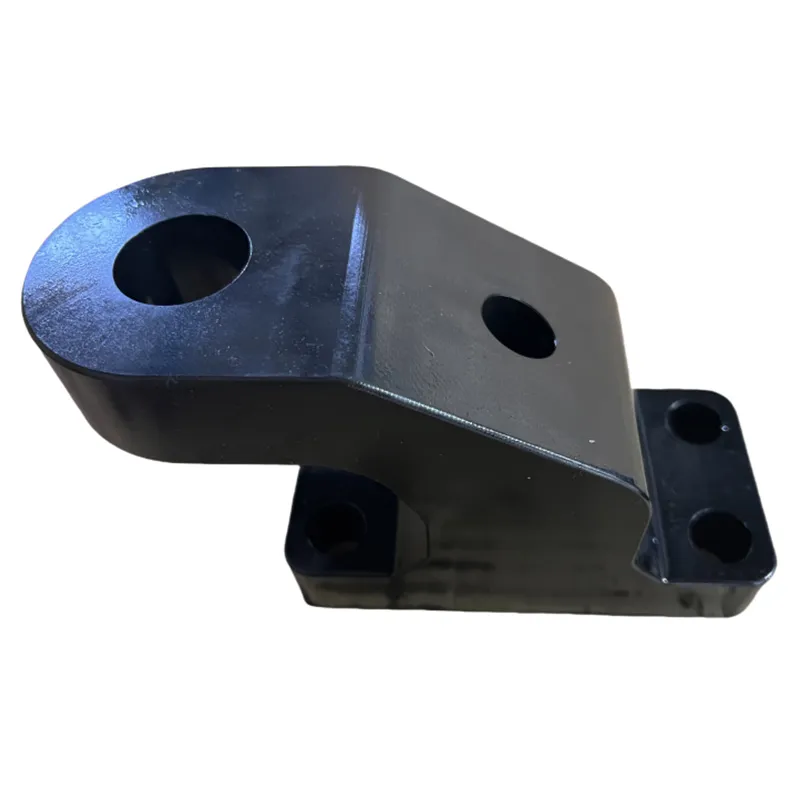

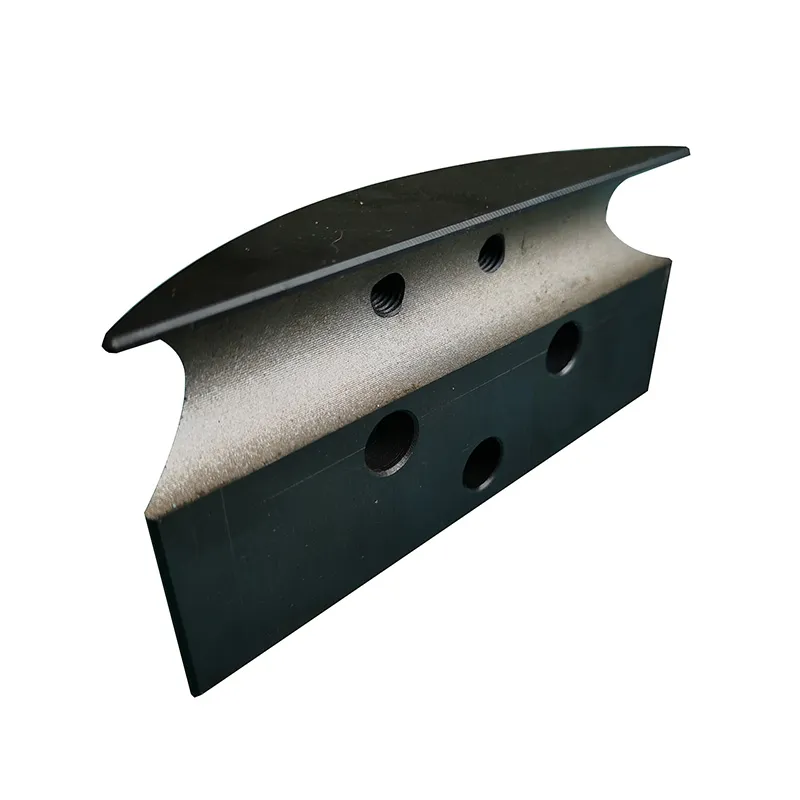

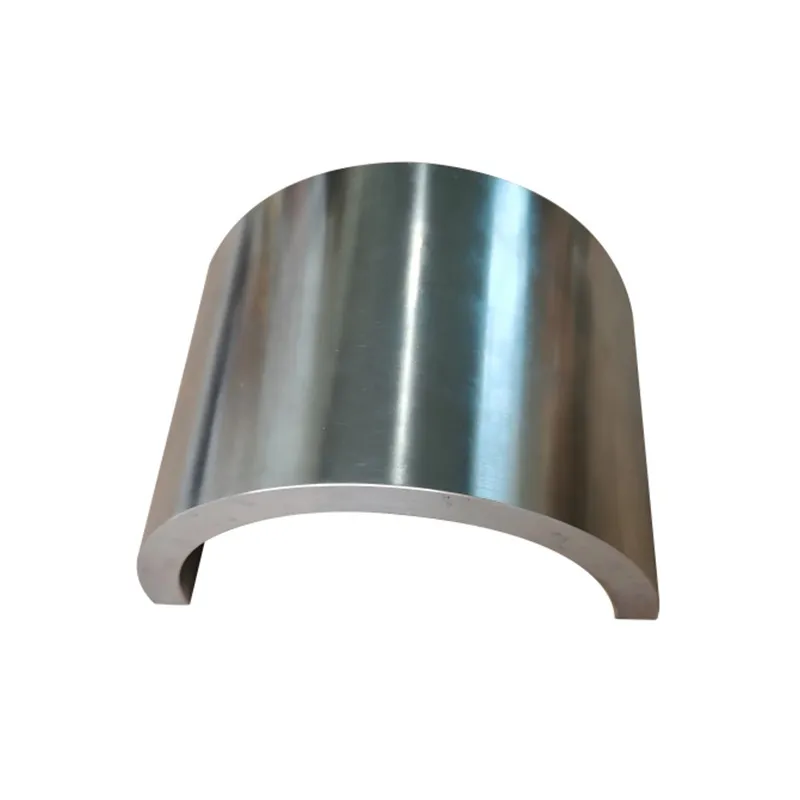

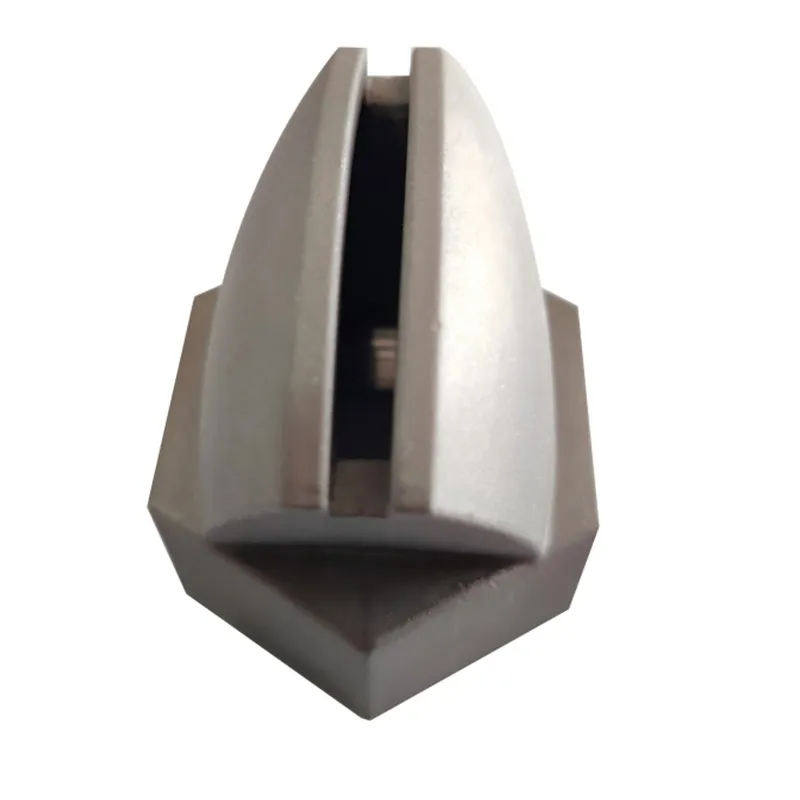

Manufacturing Process:

Considering the raw material price, the part's structure, and the processing difficulty, we adopted a direct machining method using bar stock. By reducing the cutting amount, increasing the cutting time, and using special tools, we achieved improved surface finish and accuracy of the shaft. After precision machining, each shaft undergoes coordinate measuring machine (CMM) inspection and surface roughness testing to ensure all dimensions meet specifications.