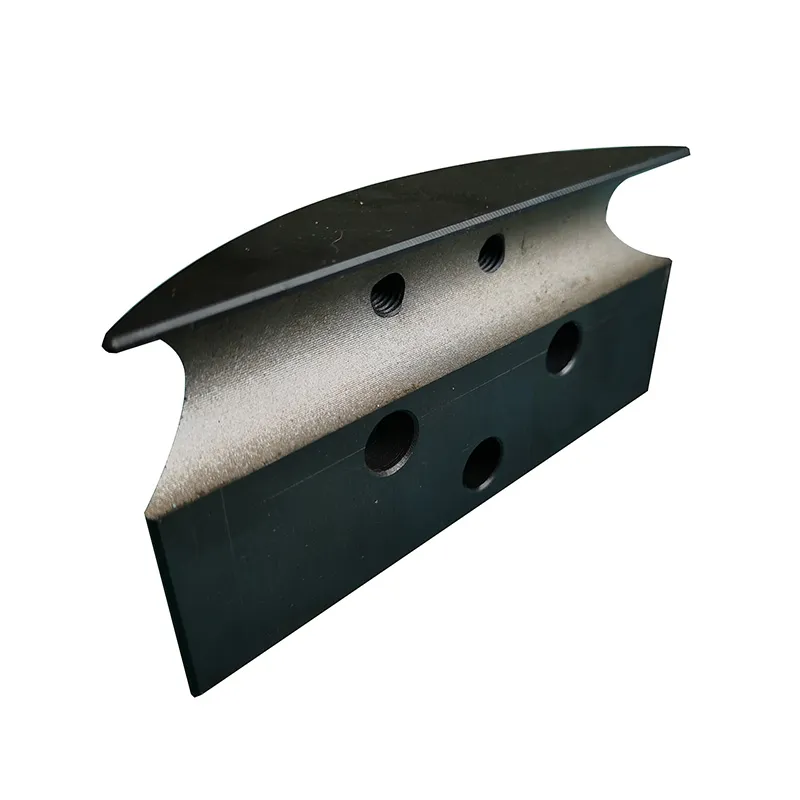

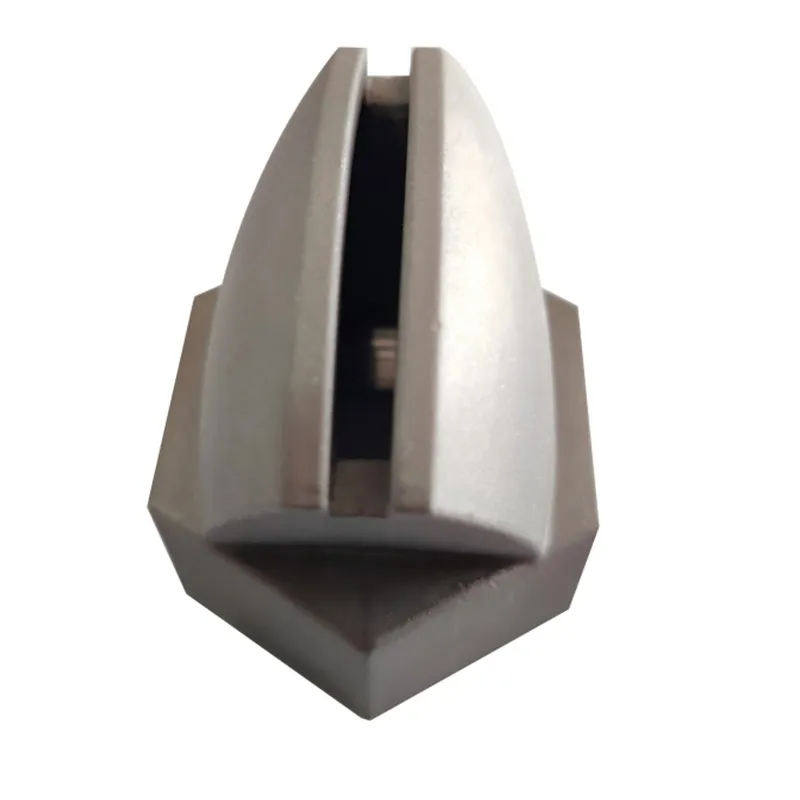

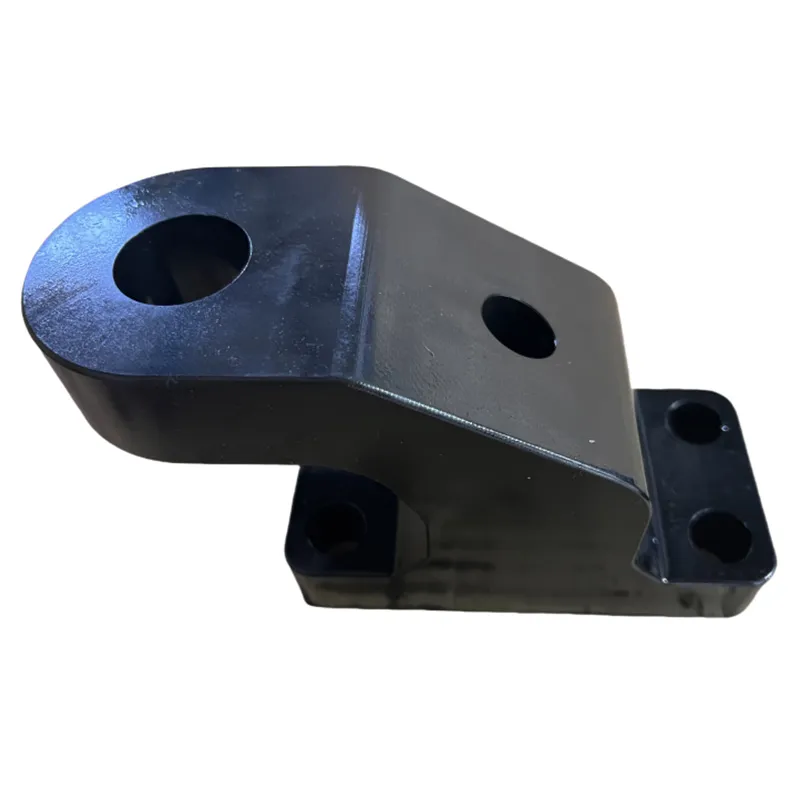

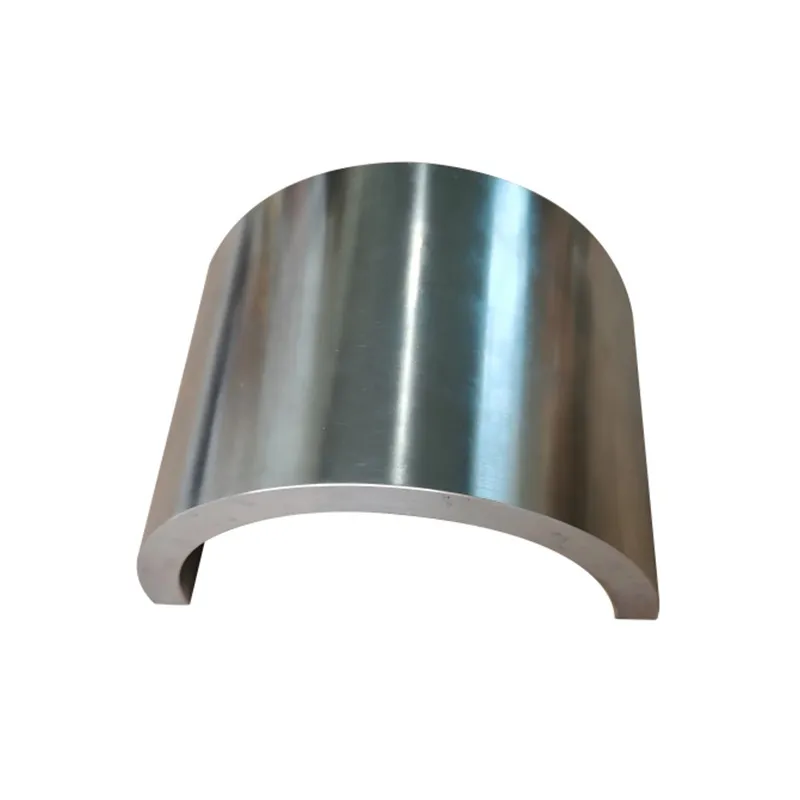

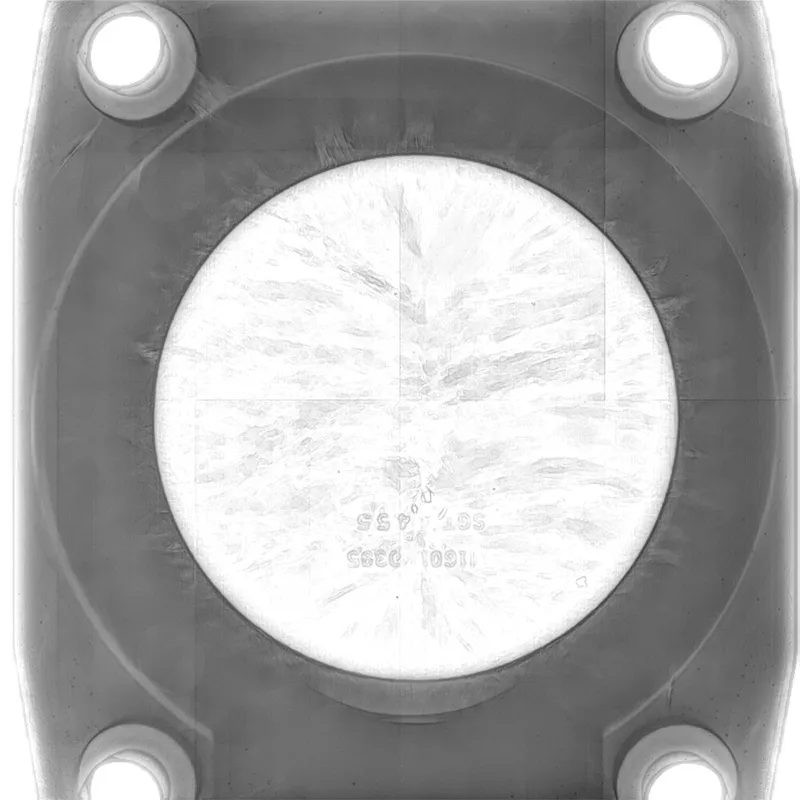

We manufacture professional, high-precision piston pump parts for a very renowned European manufacturer of paint spraying equipment. The pump body is made of 1.4112 stainless steel. 1.4112 is a high-carbon martensitic stainless steel with ultra-high hardness, high wear resistance, and good corrosion resistance. It also exhibits minimal deformation during heat treatment and can achieve a mirror-like surface finish, making it suitable for precision parts.

Material Composition and Mechanical Properties Parameters:

1.4112 Stainless Steel Composition Table

| Chemical Composition |

| Elements |

C |

Mo |

Cr |

V |

Si |

P |

S |

Mn |

Fe |

| Percentage(%) |

0.85-0.95 |

0.9-1.3 |

17.9-19.0 |

0.07-0.12 |

≤ 1.0 |

≤ 0.04 |

≤ 0.03 |

≤ 1.0 |

Bal. |

2.Mechanical Properties:

(1).Tensile Strength (T.S): ≥590 MPa

(2).Yield Strength (Y.S): ≥245 MPa

(3).Elongation (E.L): ≥15%

(4).Brinell Hardness (HB): 230 - 255

After heat treatment, the mechanical properties of the material will change significantly. Hardness can reach 58-60 HRC, tensile strength can reach 750-950 MPa, and yield strength can exceed 550 MPa.

Manufacturing Process:

This part has extremely strict dimensional requirements, and the inner wall needs to achieve a mirror-like finish. The part is first manufactured using the investment casting process. After casting, the part undergoes multiple precision machining operations to meet the accuracy requirements of the assembly surfaces. Finally, the inner cavity is precision ground using a honing process to achieve the required inner wall roughness.