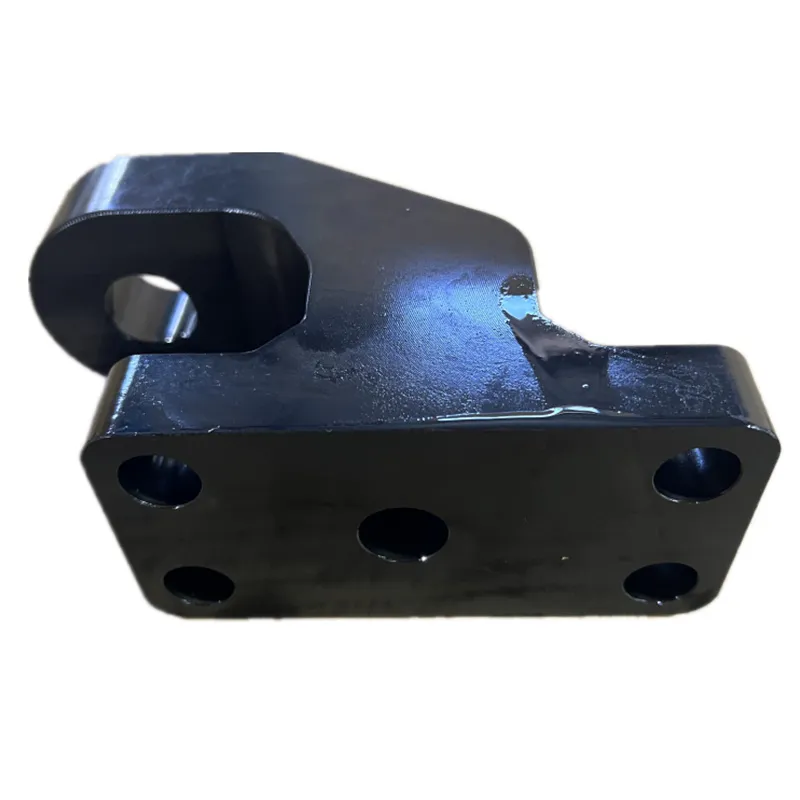

The electric bus pivot mount bracket is a core safety component that ensures the vehicle's straight-line driving stability and steering return performance.

Simply put, it serves as the physical carrier for the critical alignment parameter known as the kingpin inclination angle, forming the foundation of the vehicle's high-speed stability, steering feel, braking safety, and tire economy. Its design must meet the requirements of high strength, high toughness, long service life, and maintenance-free operation to address the unique challenges posed by the weight, power, and smoothness of electric buses.

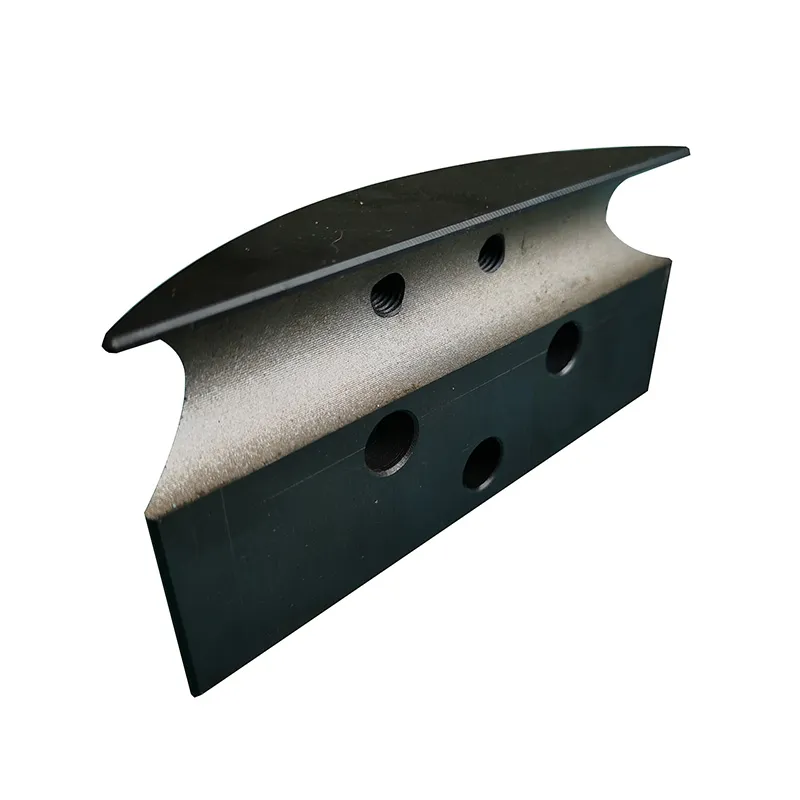

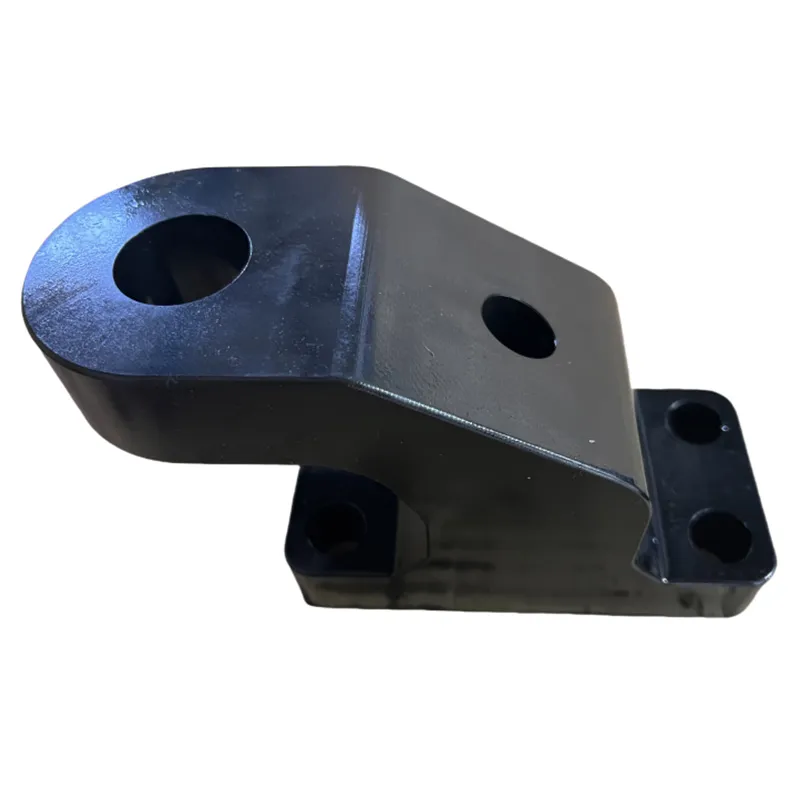

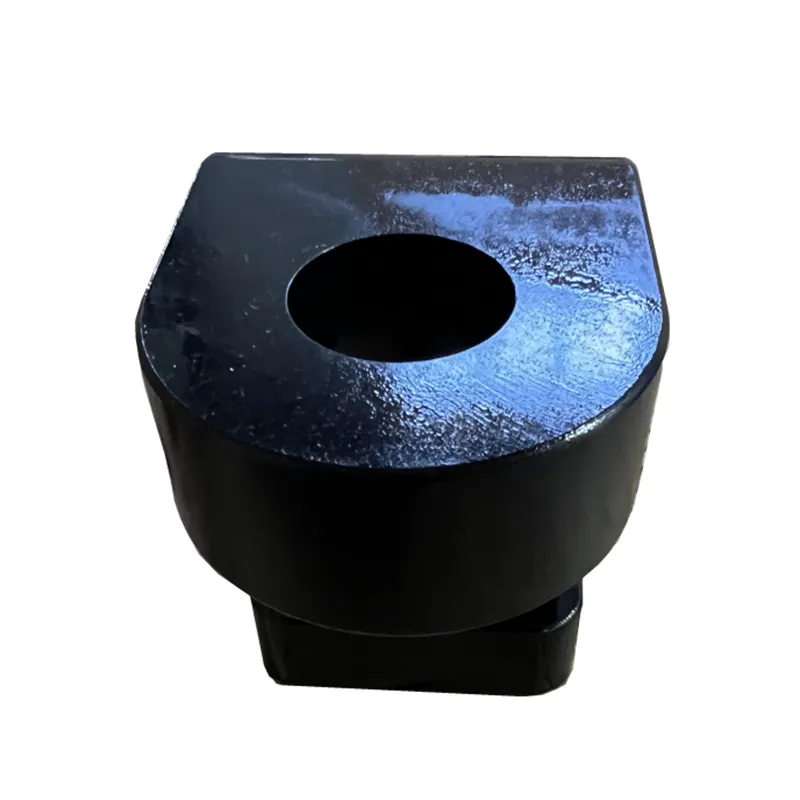

The electric bus pivot mount bracket we manufacture is made of chromium-molybdenum steel 4140, characterized by high strength, high toughness, and excellent fatigue strength, with a blackened surface treatment for rust prevention.

Material Composition and Mechanical Performance Parameters:

1.Chrome-molybdenum steel 4140 Composition Table

| Chemical Composition |

| Elements |

C |

Mn |

Si |

Cr |

Mo |

P |

S |

Fe |

| Percentage(WT%) |

0.38-0.43 |

0.75-1.00 |

0.15-0.35 |

0.80-1.10 |

0.15-0.25 |

≤0.035 |

≤0.040 |

Bal. |

2.Mechanical Properties

(1).Tensile Strength (T.S): ≥650 MPa

(2).Yield Strength (Y.S): ≥400 MPa

(3).Elongation (E.L): ≥16%

(4).Brinell Hardness (HB): ≤ 217

Manufacturing Process:

Processing using 42CrMo steel plate.

Step 1: Use a vertical machining center to mill the outer side profile of the product and achieve the total width.

Step 2: Clamp the product vertically to machine holes and chamfer the product edges.

Step 3: Flip the product 180° to machine stepped holes.

Step 4: Use a CNC lathe with specialized clamping fixtures to machine inclined holes.