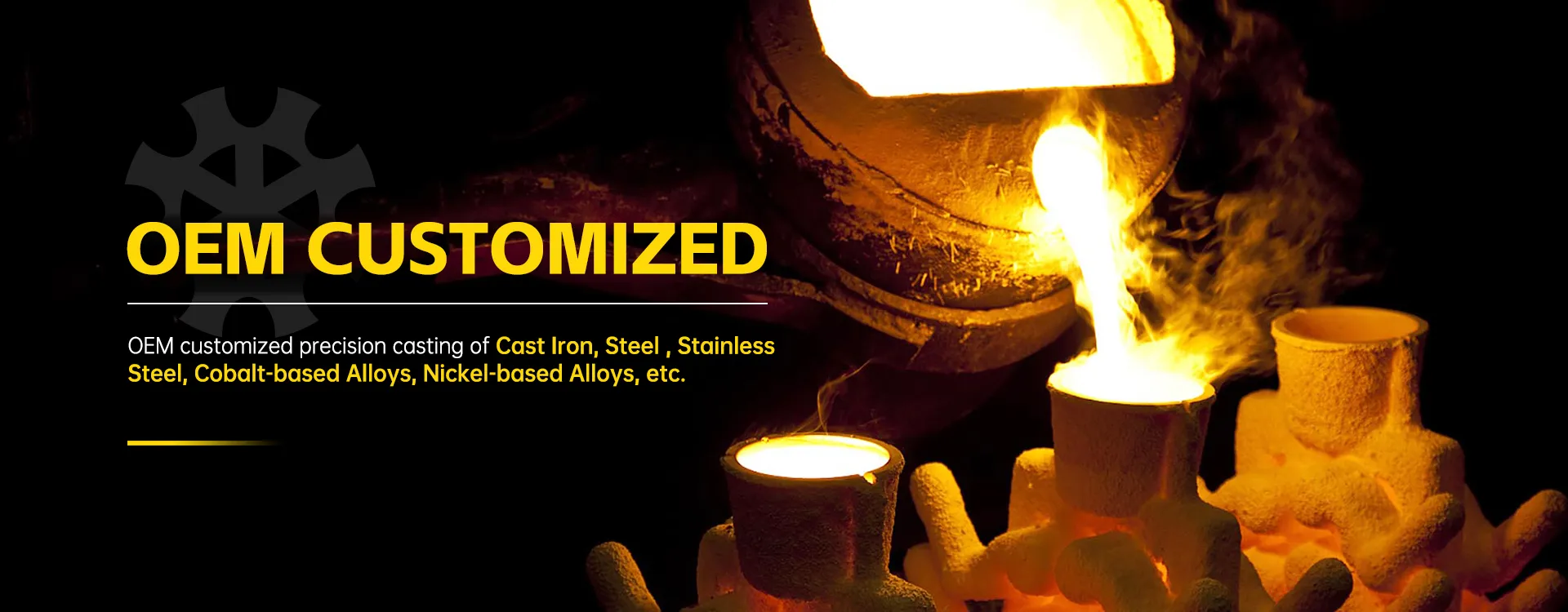

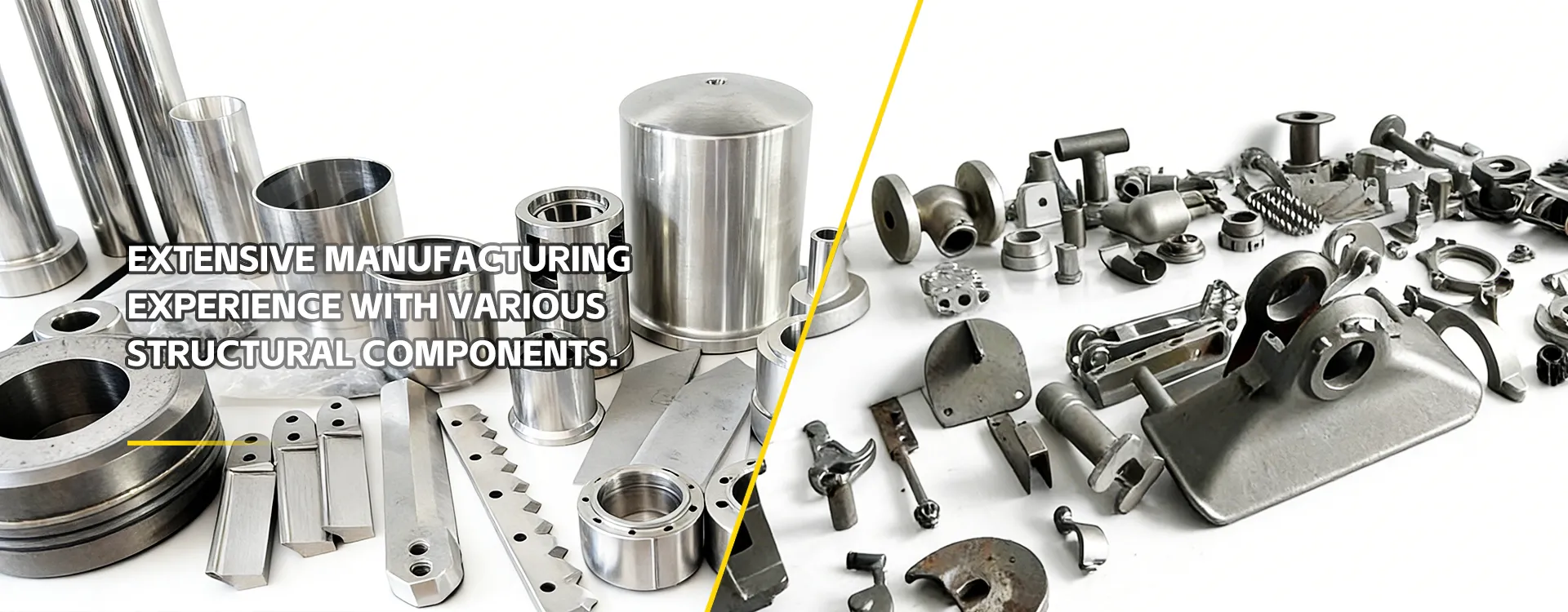

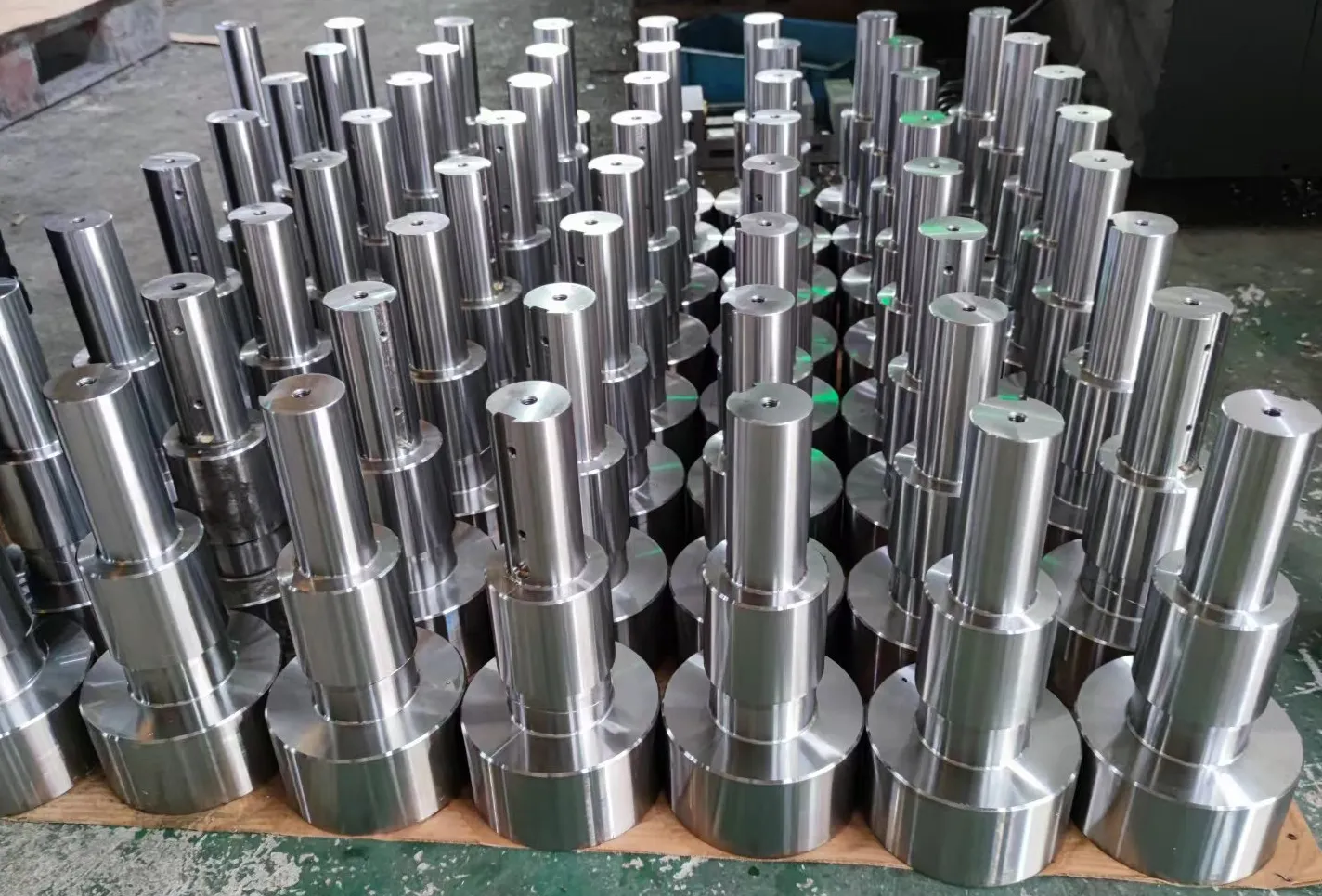

Investment casting(kurasika-wax casting) inzira inoshandisa chaiyo, inoraswa modhi yakagadzirwa nefusible wax material. Iyi modhi inozoputirwa nemateru akawanda ezve refractory kuti igadzire yakazara mold shell. Wakisi modhi inonyungudutswa nekudziisa, zvoita kuti pave negoko redongo redongo redongo rinonyatso tevedzera chimiro chemhando yewakisi yepakutanga. Simbi yakanyungudutswa inobva yadirwa mugoko reforoma, yozobuditsa simbi yakafanana neyekutanga wakisi. Iyi maitiro inyanzvi yakakosha tekinoroji mukugadzirwa kwepamusoro-soro, kunyanya yakakodzera kugadzirwa kwezvinhu zvakakosha zvine maumbirwo akaomarara, zvinhu zvinodhura, uye zvinoda kuita zvinodiwa. Tichishandisa maitiro aya, tinokwanisa kugadzira mativi akakwana akagadzirwa nezvinhu zvakasiyana-siyana, zvinosanganisira simbi, simbi isina tsvina, uye alloys akakosha (senge aruminiyamu alloys, nickel-based alloys, uye akakosha simbi isina tsvina, nezvimwewo).