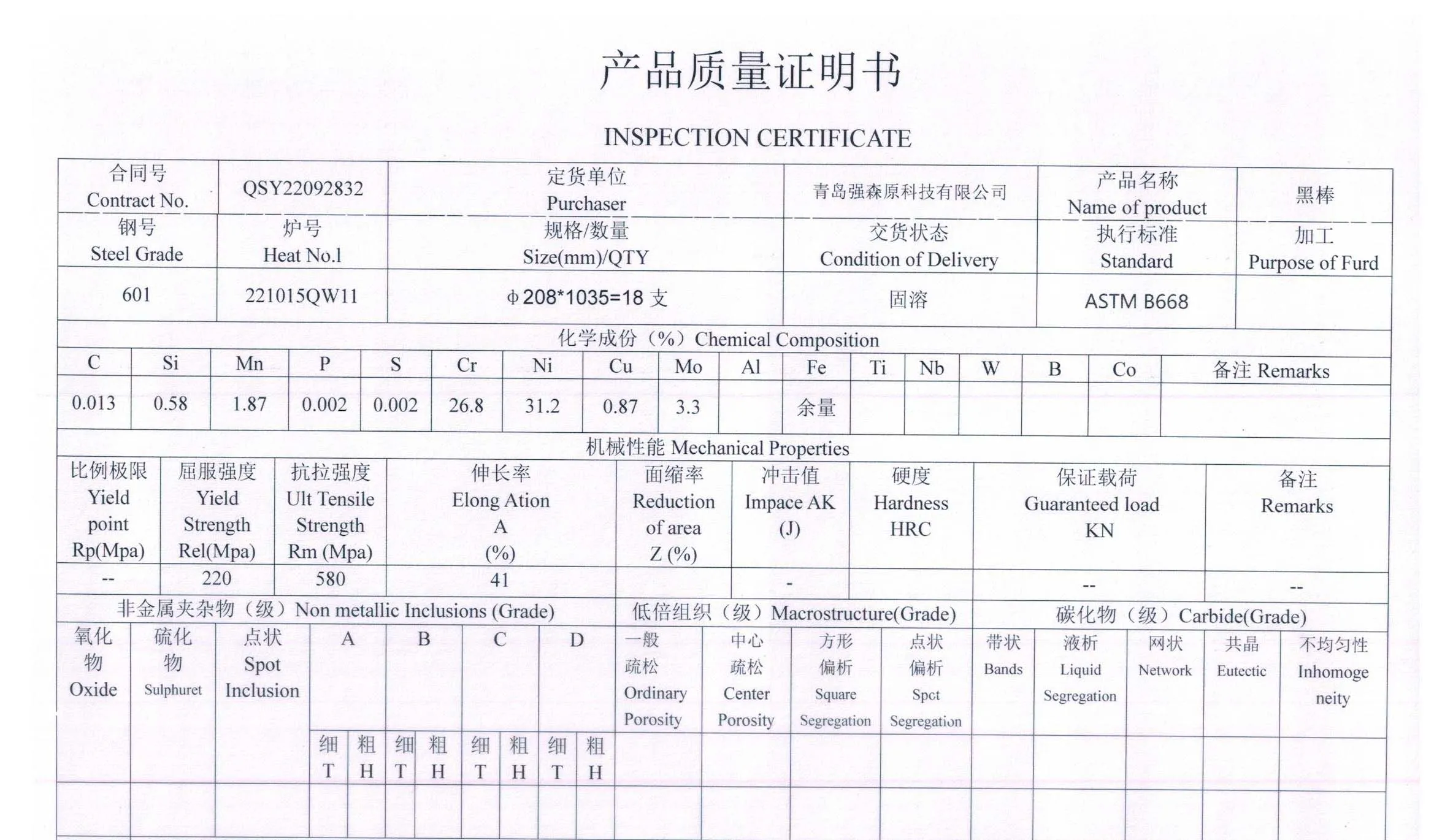

1.Zvinhu: Alloy 28(N08028,4563,X1NiCrMoCu31-27-4)

Chemical Component:C ≤0.02%;Si:≤1.0%;Mn:≤2.0%;P:≤0.03%;S :≤0.03%;Cr :26~28%;Ni :30~32%;Mo: 3~40%;

2.Zvinhu:

density:8.1g/cm³;

melting point: 1320-1370 ℃;

simba rekuwedzera:1650-2250MPa;

goho simba:1250-1750MPa;

mwero werefu:25% -45%;

kuoma:35-45HRC

3.Main Property:

Kupikisa kupisa kwekupisa, kupikisa kupfeka kwepamusoro, kumira zvakanaka kwekuora, kuoma kwakanaka kwakatsvuka; Kuramba kwakanaka kwekuora munzvimbo yakasimba yeasidhi; Kuramba kwakanaka kumanikidziro ekuparara kwekuputika muhydrogen sulfide (H2S) uye chloride nharaunda; Yakanaka intergranular corrosion resistance; Kunyanya kupikisa kugomba uye kuora kwegomba; Weldability yakanaka;

4.Alloy 28 Nzvimbo dzekushandisa:

Inowanzo shandiswa muhukasha hwekuora midhiya senge indasitiri yemakemikari, uye inogona kushandiswa mukugadzira makemikari, midziyo yekudzora kusvibiswa, oiri uye gasi tsime pombi, kugadzirwa kwemafuta enyukireya, masevhisi epasi pevhu munzvimbo yakadzika sarufa gasi Wells, pamwe nekugadziriswa kwemakemikari ekunyorova phosphoric acid, mvura yegungwa, hydrofluorinated chloride uye organic acid kugadzira uye pickling michina.

5.Processing Zvinodiwa:

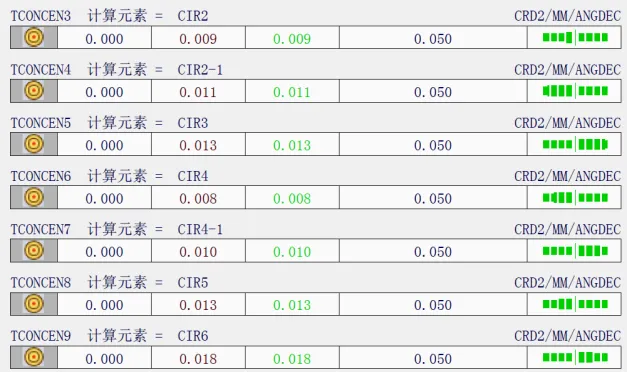

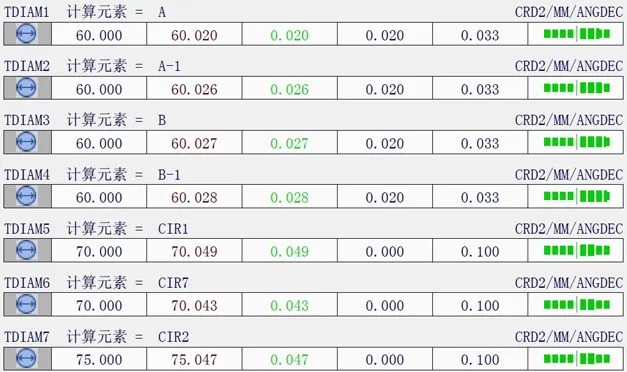

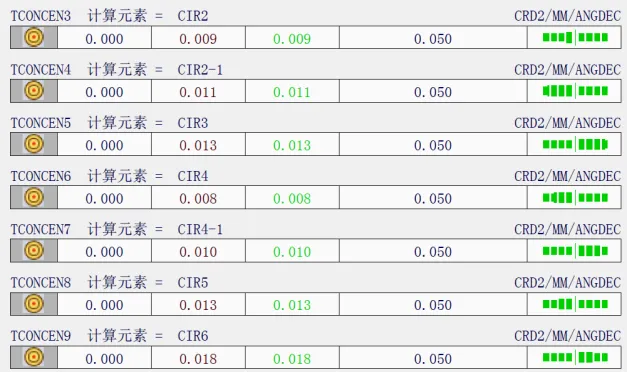

Iyo yepamusoro machining iko 0.01mm, iyo yepamusoro yekupedzisira iRA0.6um, uye concentricity yezvese kunze kwedenderedzwa nzvimbo iri mukati me 0.05mm.

6.Machining process:

Raw material forging:sanicro28 is an unconventional stainless steel material, inodhura, uye yakakura chimiro, kureba kwekunze kwedhayamita i200MM, hapana bhaa zvinhu zveiyi dhizaini, kushandiswa kwekugadzira kugadzira makushe embryo, nekuda kwekuoma kwakanyanya kwechinhu, chakanyanya kukodzera kuforoma bhari zvinhu sechinhu chisina kugadzirwa. Hukuru hwemambure echishandiso mushure mekugadzirisa ndeye 200 yekunze dhayamita uye 1028 kureba, uye shinda yakaumbwa inoshandiswa ndeye 210 kunze kwedhayamita uye 1100 kureba.

Kugadzirisa kuoma:Nekuda kwekuti zvinhu zvacho zvine chromium yakakwira uye ine chikamu chemolybdenum, zvichikonzera kuoma kwakanyanya kweiyo workpiece, zviri munickel zvakare zvakakwirira, kuoma kwezvinhu kwakakwira, kugadzirisa kwakaoma, uye zviri nyore kuoneka chip breaking and sticking banga uye resonance matambudziko. blade, iyo inogadzirisa dambudziko rekugadzirisa kushanda uye kunamatira chigadziro, uye dambudziko resonance ye workpiece uye chigadziro chekushandura.Kushandisa imwe nzira yekugadzira purogiramu, kushandiswa kwema cyclic kushanduka kwekushanda kwekushanda uye kukurumidza kwekudya, yekupedzisira yakakwana yekugadzirisa dambudziko resonance.

Kuomesera kuomarara: Iyo workpiece viscosity yakakura, zvichikonzera marara akakomba eiyo adhesion material yeguyo rekukuya, uye hazvibviri kugaya zvakajairika. Chekupedzisira, iyo lathe yekupedzisa chirongwa inoshandiswa kuzadzisa chinodiwa chepamusoro pekupedzisira RA0.6um.

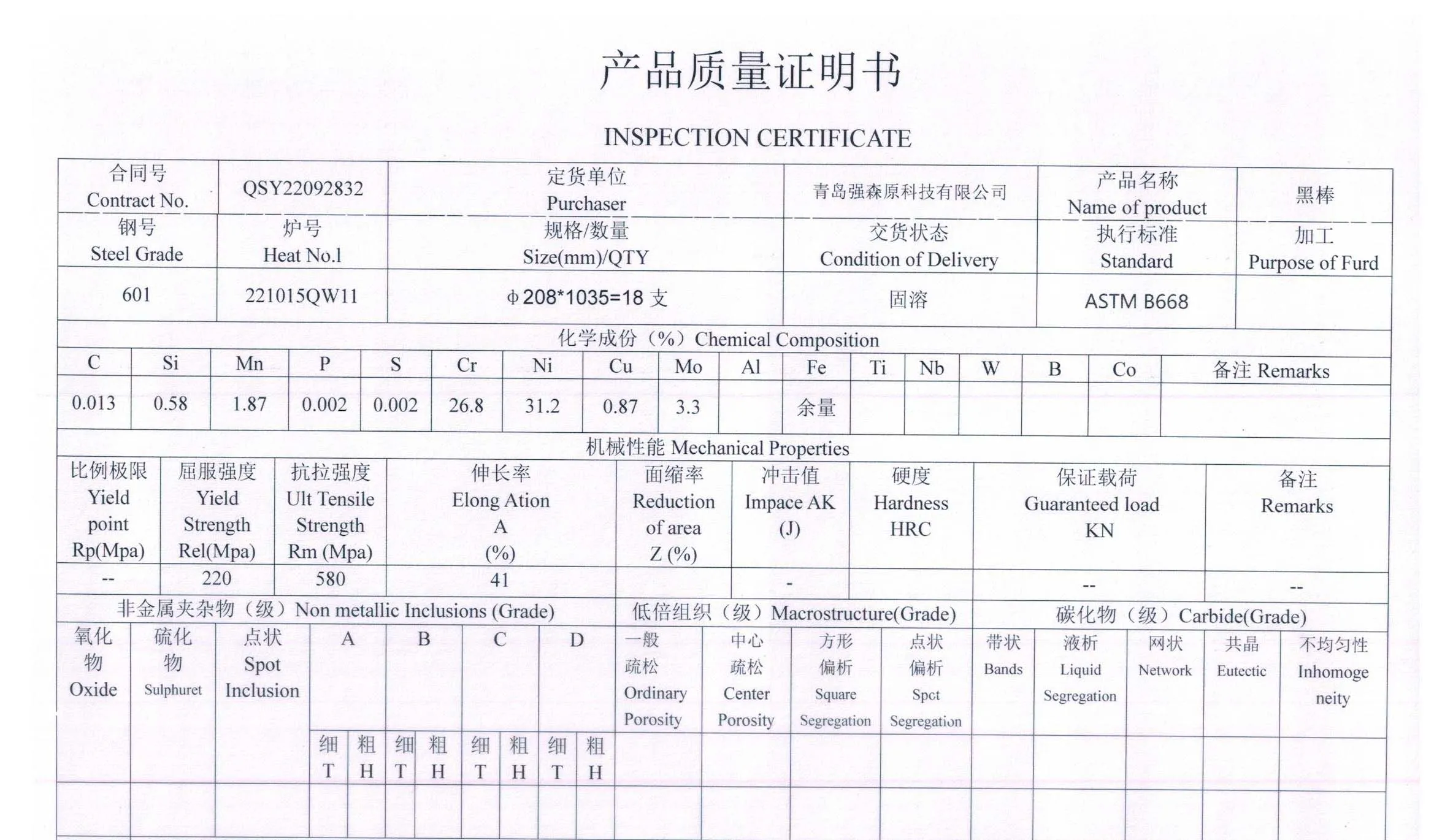

7.Material Report

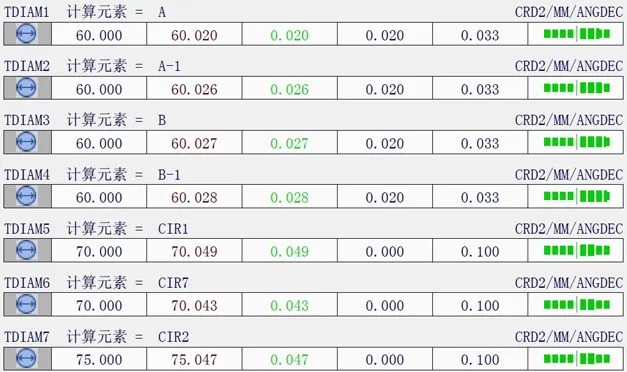

8.Coordinate Measuring(CMM chiyero)