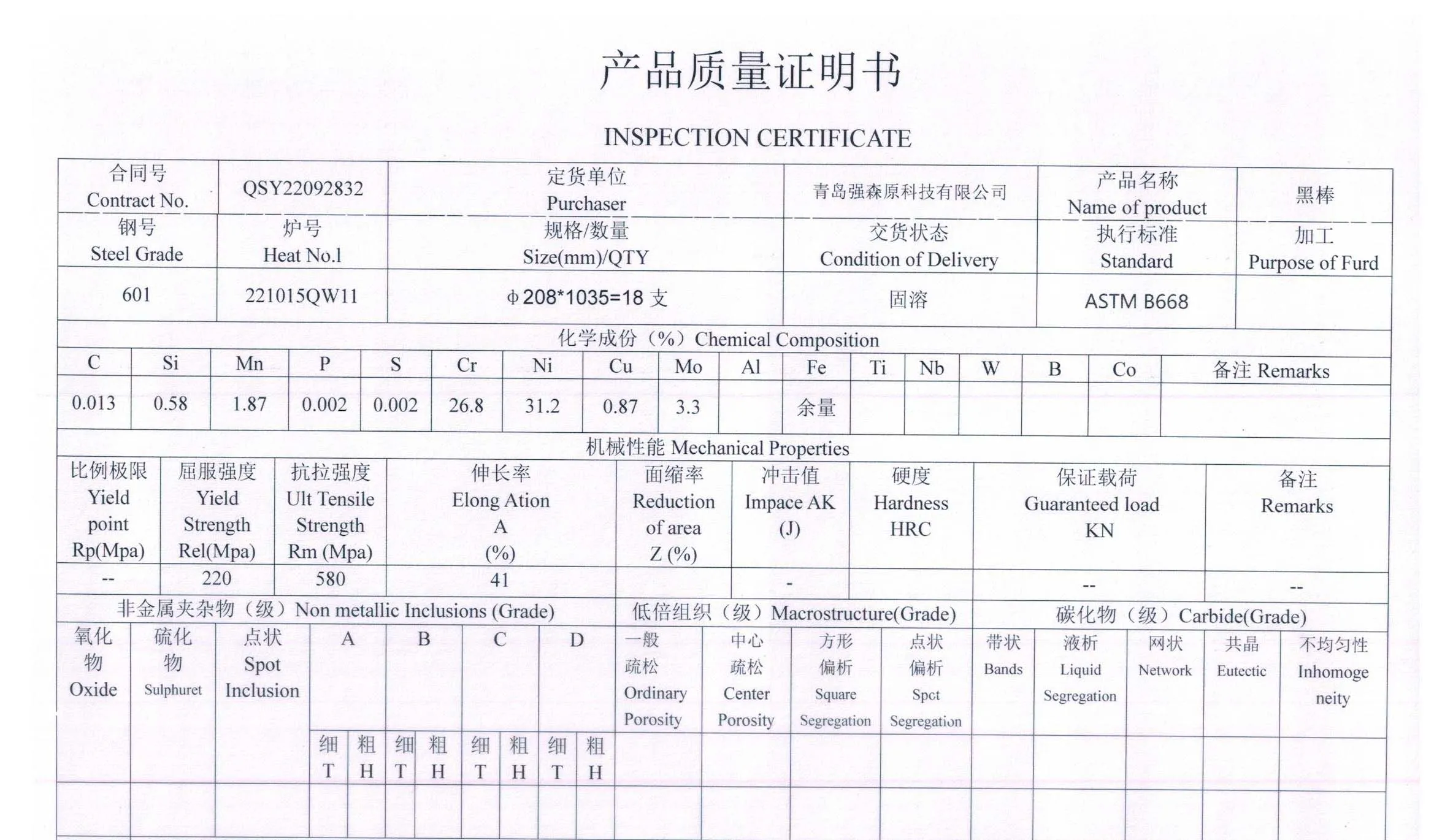

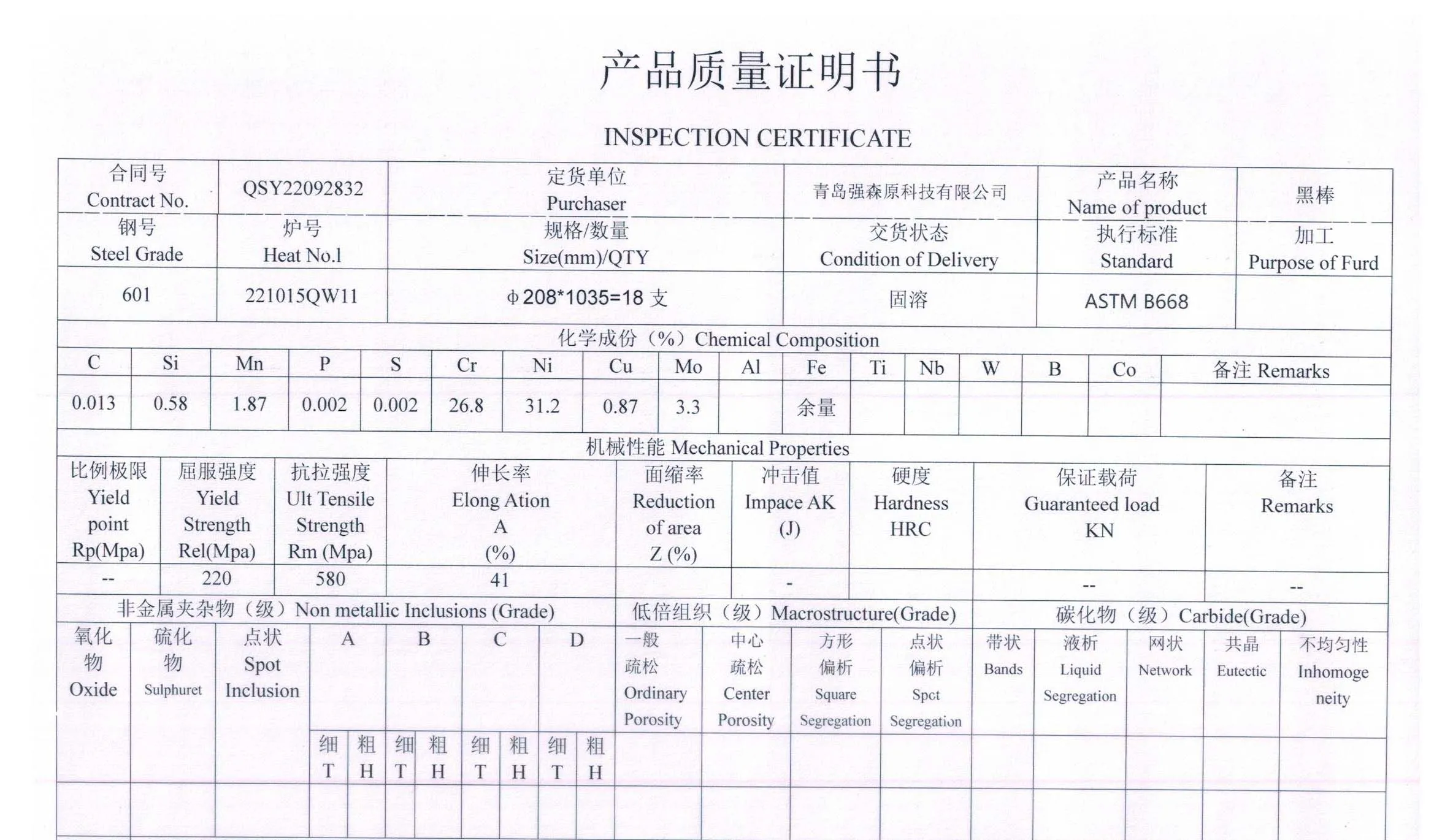

1.Material: Alloy 28(N08028,4563,X1NiCrMoCu31-27-4)

Motsoako oa Lik'hemik'hale:C ≤0.02%;Si:≤1.0%;Mn:≤2.0%;P:≤0.03%;S :≤0.03%;Cr :26~28%;Ni :30~32%;Momar: 3~40%;Cu : 3~40%;

2.Thepa ea Material:

tekano:8.1g/cm³;

ntlha ea ho qhibiliha: 1320-1370 ℃;

matla a ho eketsa:1650-2250MPa;

fana ka matla:1250-1750MPa;

sekhahla sa bolelele:25% -45%;

thatafalo:35-45HRC

3.Thepa e kholo:

Ho hanyetsa mocheso oa mocheso, khanyetso e phahameng ea ho apara, ho hanyetsa ha kutu e ntle, boima bo botle bo bofubelu; Khanyetso e ntle ea kutu tikolohong e matla ea asiti; Ho hanyetsa hantle khatello ea maikutlo ho senyeha ha hydrogen sulfide (H2S) le tikoloho ea chloride; Ho hanyetsa ho bola ha intergranular; Ho hanyetsa ho hoholo ha likoti le ho bola ha likoti; Weldability e ntle;

4.Alloy 28 Libaka tsa Kopo:

E sebelisoa hangata mecheng ea litaba tse senyang joalo ka indasteri ea lik'hemik'hale, 'me e ka sebelisoa ho sebetsana le lik'hemik'hale, lisebelisoa tsa taolo ea tšilafalo, liphaephe tsa liliba tsa oli le khase, ho lokisa mafura a nyutlelie, lits'ebeletso tsa ts'ebetso ea ka tlas'a lefatše ka har'a metsi a tebileng a sebabole, hammoho le ts'ebetso ea lik'hemik'hale ea acid e metsi ea phosphoric, metsi a leoatle, hydrofluorinated chloride le tlhahiso ea asiti ea organic le lisebelisoa tsa ho hula.

5. Litlhoko tsa ho sebetsa:

Ho nepahala ho phahameng ka ho fetisisa ha mochine ke 0.01mm, qetello e phahameng ka ho fetisisa ke RA0.6um, 'me ho teba ha libaka tsohle tse chitja tse ka ntle ho ka hare ho 0.05mm.

Mokhoa oa 6.Machining:

Lisebelisoa tse tala: sanicro28 ke thepa e sa tloaelehang ea tšepe e sa hloekang, e theko e boima ebile e le sebōpeho se seholo, bophara ba ka ntle ke 200MM, ha ho na thepa ea bar ea tlhaloso ena, tšebeliso ea ho etsa forging ho hlahisa embryo ea boea, ka lebaka la boima bo phahameng ba thepa, e loketseng ka ho fetisisa bakeng sa lisebelisoa tsa bar e le mokhoa o se nang letho. Boholo ba letlooa la workpiece ka mor'a ho sebetsa ke bophara ba 200 ka ntle le bolelele ba 1028, 'me boea bo entsoeng bo sebelisitsoeng ke bophara ba 210 ka ntle le bolelele ba 1100.

Bothata ba ho sebetsa:Hobane thepa e na le lintho tse ngata tsa chromium 'me e na le karolo ea molybdenum, e bakang boima bo phahameng ba mosebetsi, bokahare ba nickel le bona bo phahame, boima ba thepa bo phahame, ho thata ho sebetsana le bothata,' me ho bonolo ho hlaha thipa le ho khomarela thipa le mathata a resonance. lehare, e rarollang bothata ba ho sebetsa ka katleho le sesebelisoa sa ho khomarela, le bothata ba resonance ea workpiece le sesebelisoa sa ho fetola.Ho sebelisa mokhoa o khethehileng oa lenaneo, tšebeliso ea liphetoho tsa cyclic ka lebelo la workpiece le lebelo la ho fepa, tharollo ea ho qetela e phethahetseng ea bothata ba resonance.

Bothata ba ho phunya: Viscosity ea workpiece e kholo, e baka lithōle tse tebileng tsa lebili la ho sila, 'me ha ho khonehe ho sila ka tloaelo. Qetellong, leano la ho qeta lathe le sebelisetsoa ho phethela tlhokahalo ea ho qeta holim'a metsi RA0.6um.

7.Tlaleho ea Lintho

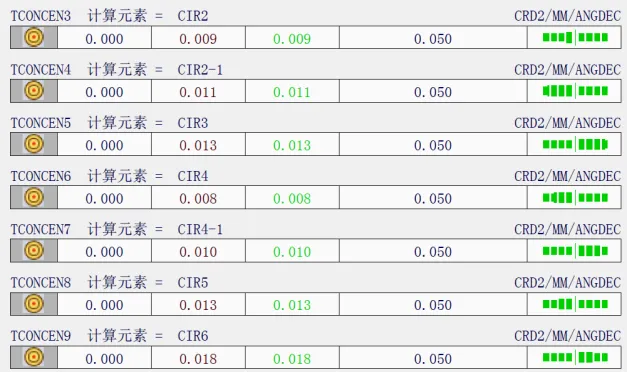

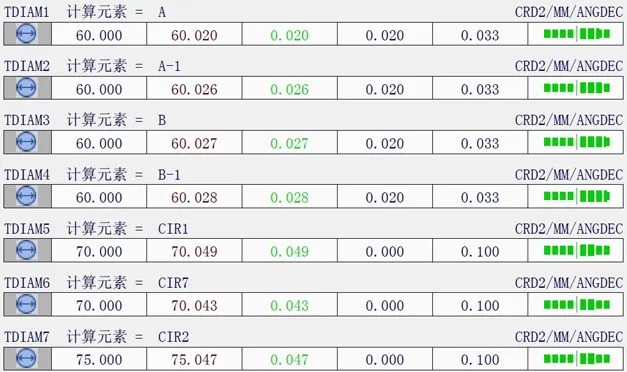

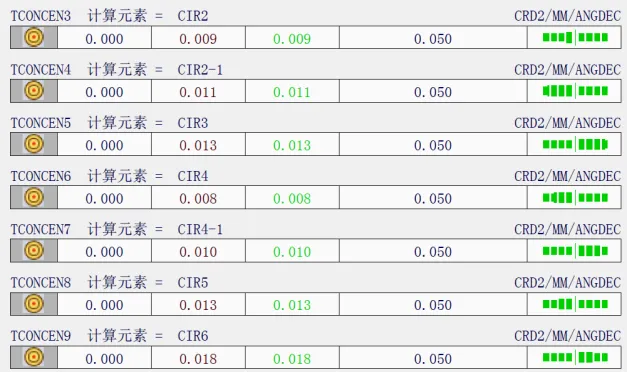

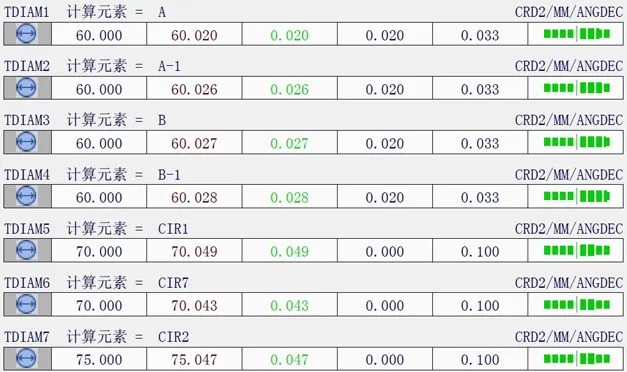

8.Coordinate Measuring(CMM tekanyo)