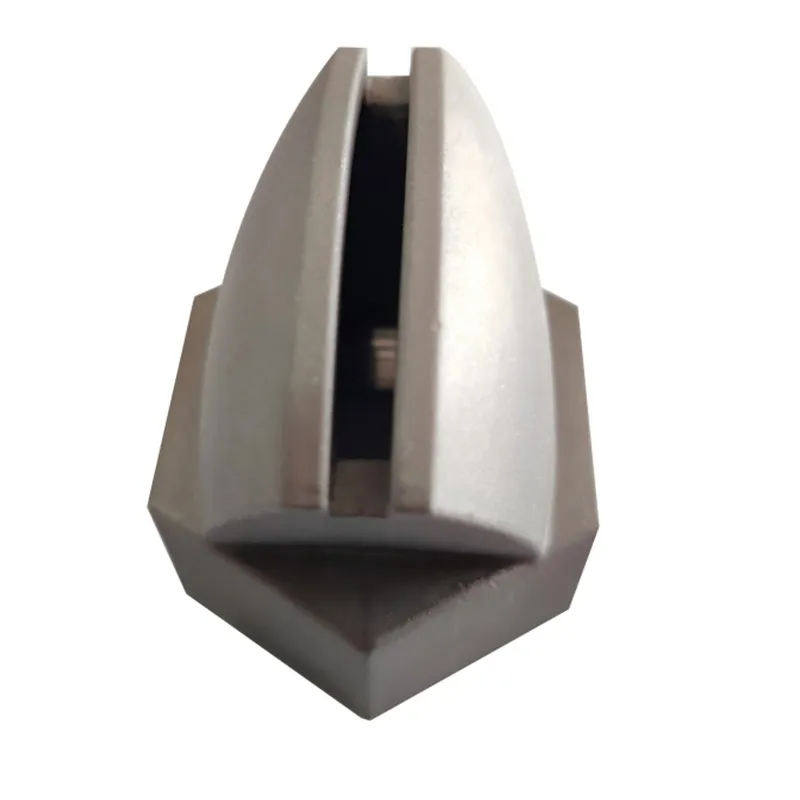

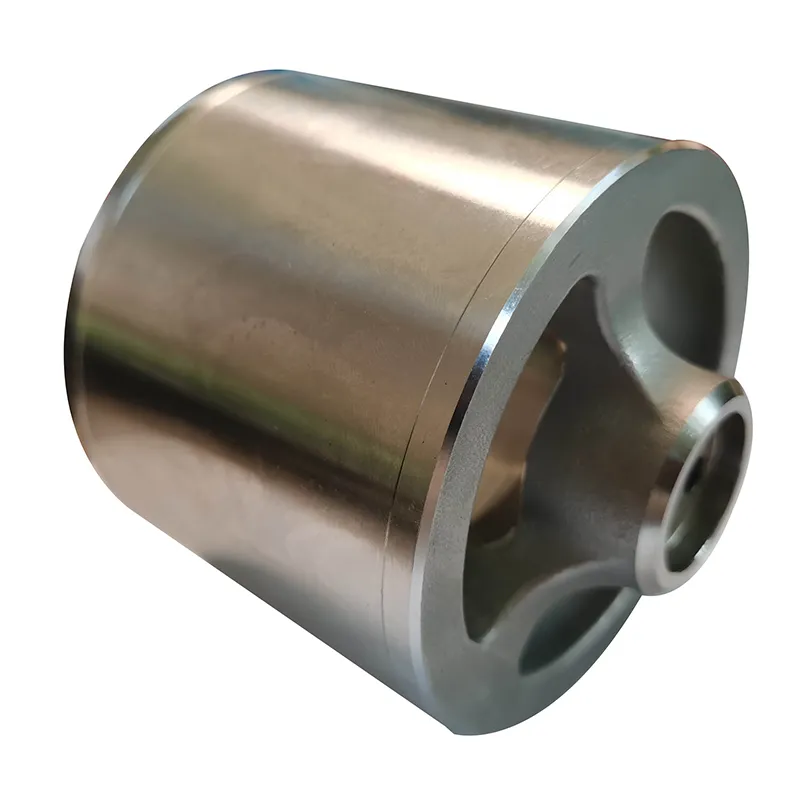

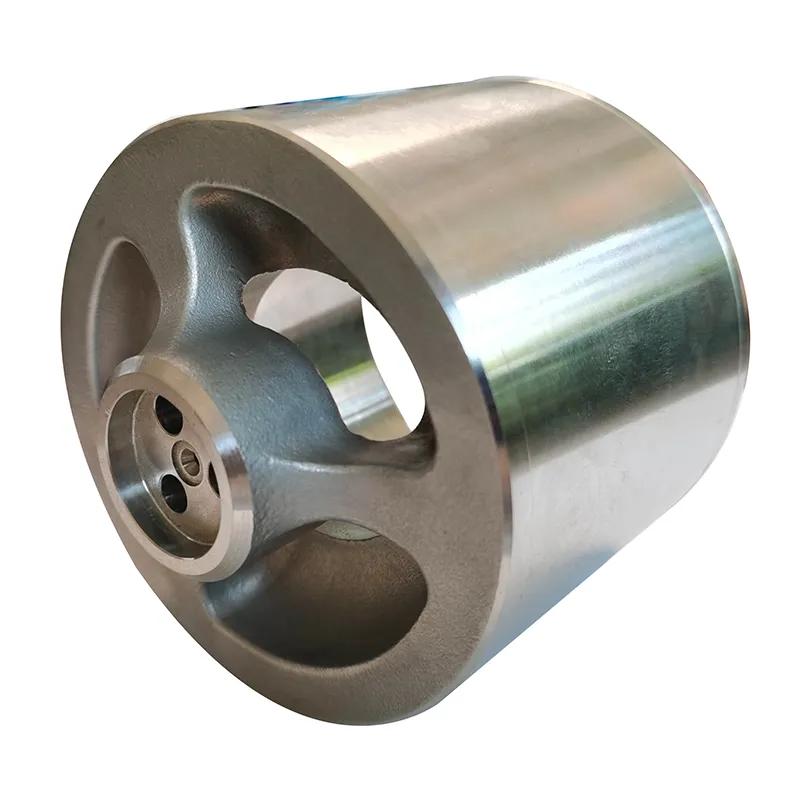

The lift check valve automatically opens and closes based on the fluid's own pressure. Its main function is to automatically prevent backflow of the medium, preventing reverse rotation of pumps and drive motors, and preventing leakage of the medium from containers. It protects pumps and other equipment by preventing backflow. Lift check valves are commonly used in pipelines in industries such as food and pharmaceuticals, petrochemicals, power generation, and metallurgy, to protect critical equipment such as pumps and compressors.

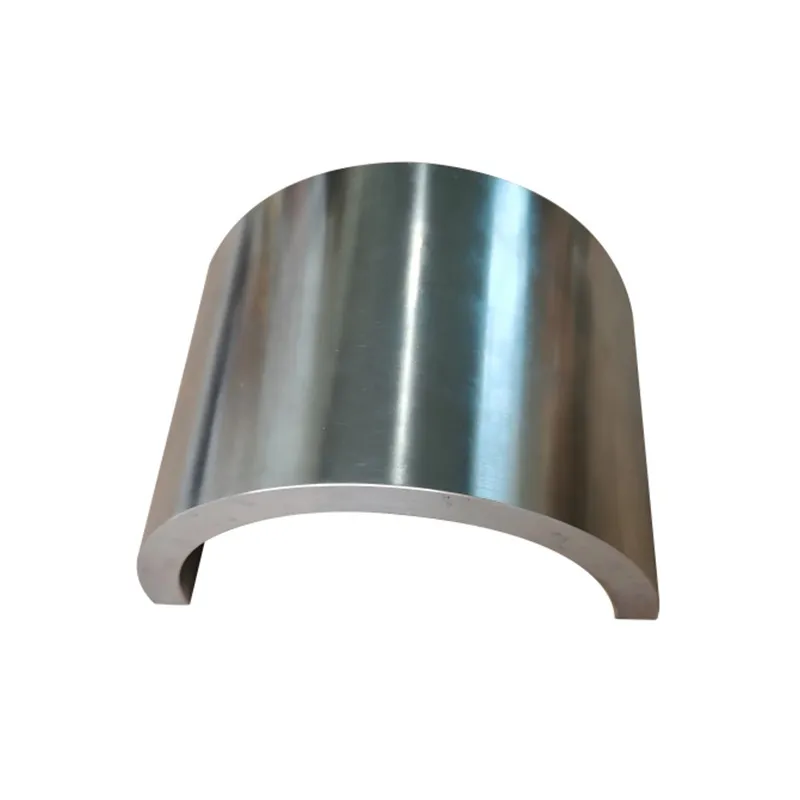

The lift check valves we manufacture are made of 304 stainless steel, which has excellent corrosion resistance and can meet the requirements of corrosive media or high-purity media environments.

Material Composition and Mechanical Performance Parameters:

1.304 Stainless Steel Composition Table

| Chemical Composition |

| Elements |

C |

Ni |

Cr |

Mn |

Si |

P |

S |

N |

Fe |

| Percentage(%) |

≤ 0.08 |

8.0-10.5 |

18.0-20.0 |

≤ 2.0 |

≤ 1.0 |

≤ 0.045 |

≤ 0.03 |

≤ 0.10 |

Bal. |

2.Mechanical Properties

(1).Tensile Strength (T.S): ≥520 MPa

(2).Yield Strength (Y.S): ≥205 MPa

(3).Elongation (E.L): ≥40%

(4).Brinell Hardness (HB): ≤ 187

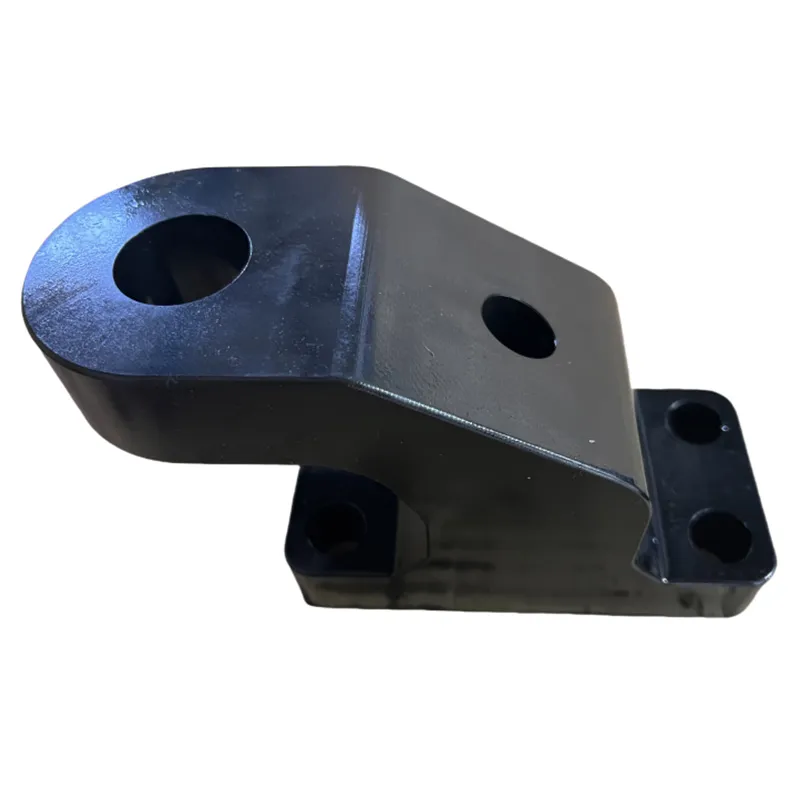

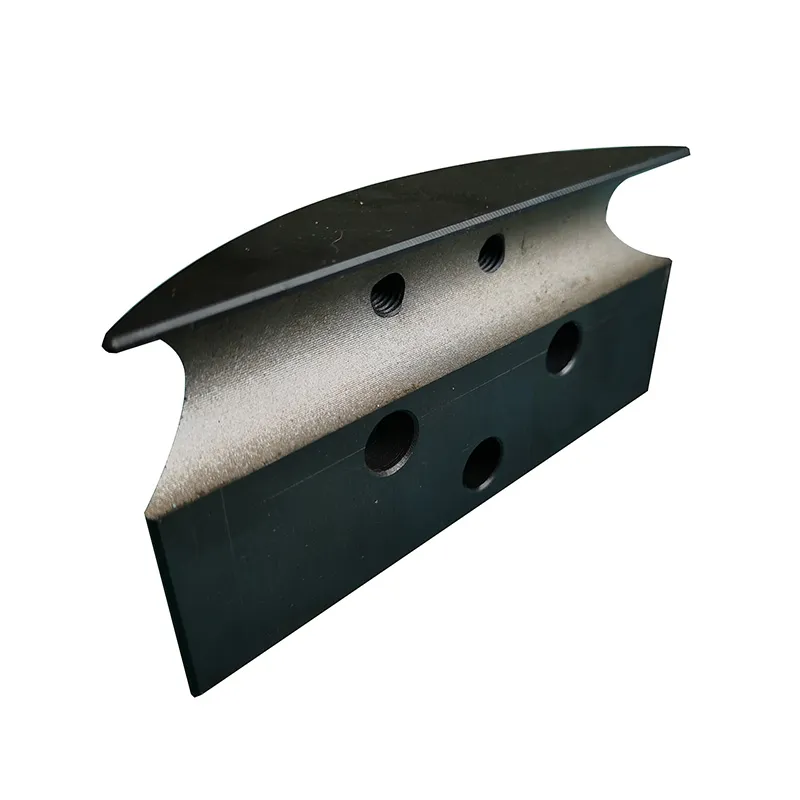

Manufacturing Process:

The parts are manufactured using the investment casting process. Investment casting is the most commonly used precision casting process for stainless steel materials, which can significantly improve surface roughness and ensure the casting accuracy of the parts. After casting, the parts undergo precision machining to meet the accuracy requirements of the assembly surfaces. After all casting and machining processes are completed, we perform coordinate measuring machine (CMM) inspection to ensure that all dimensions meet the specifications.