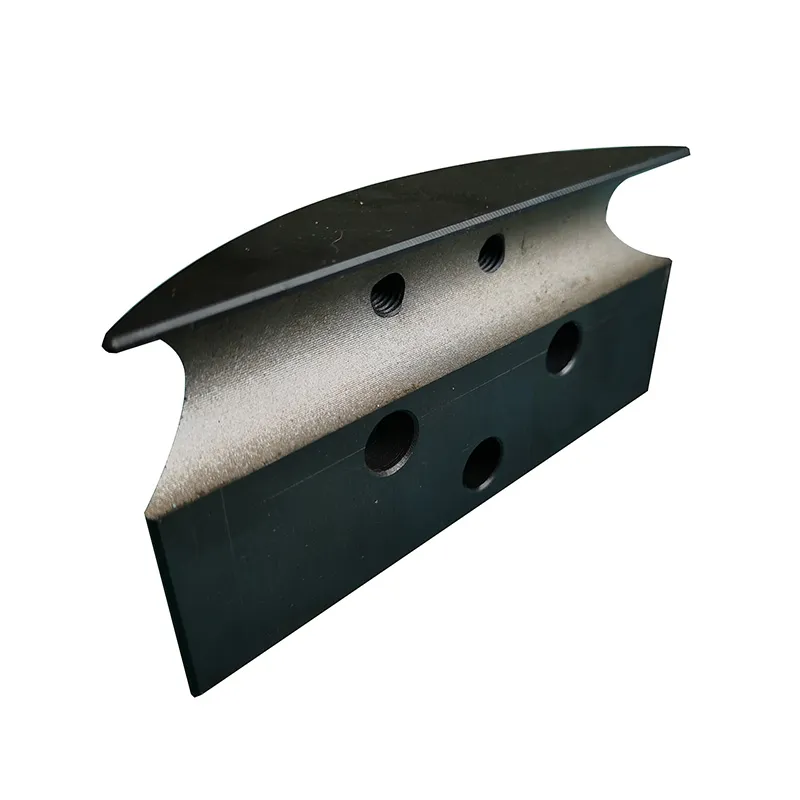

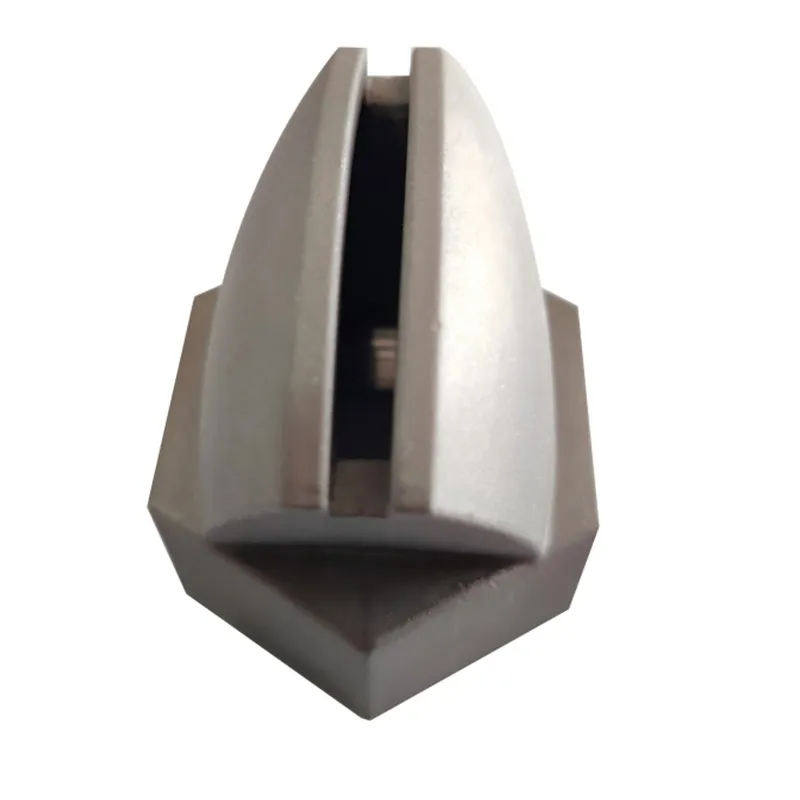

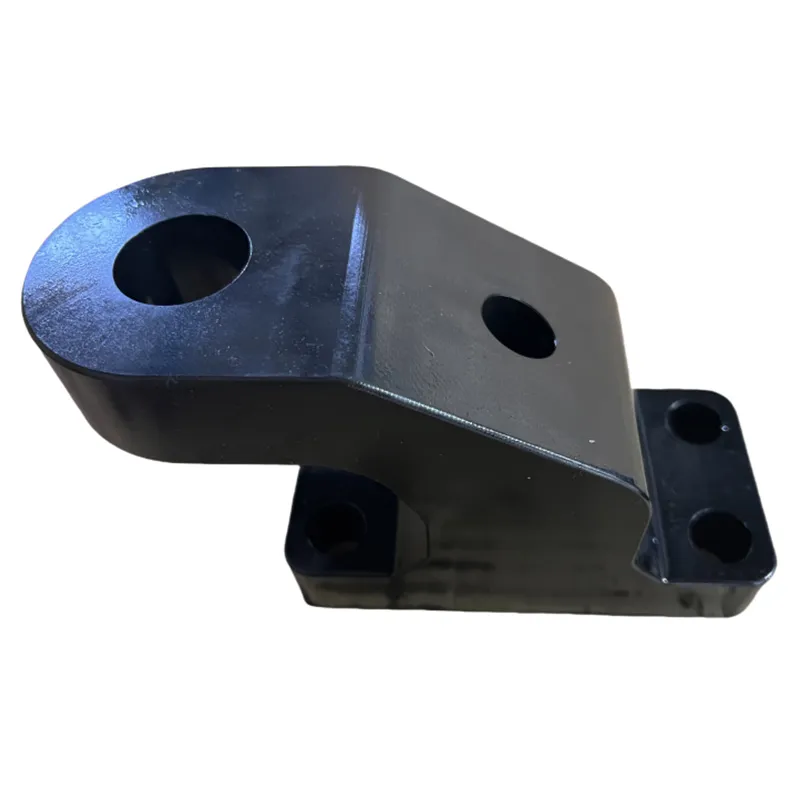

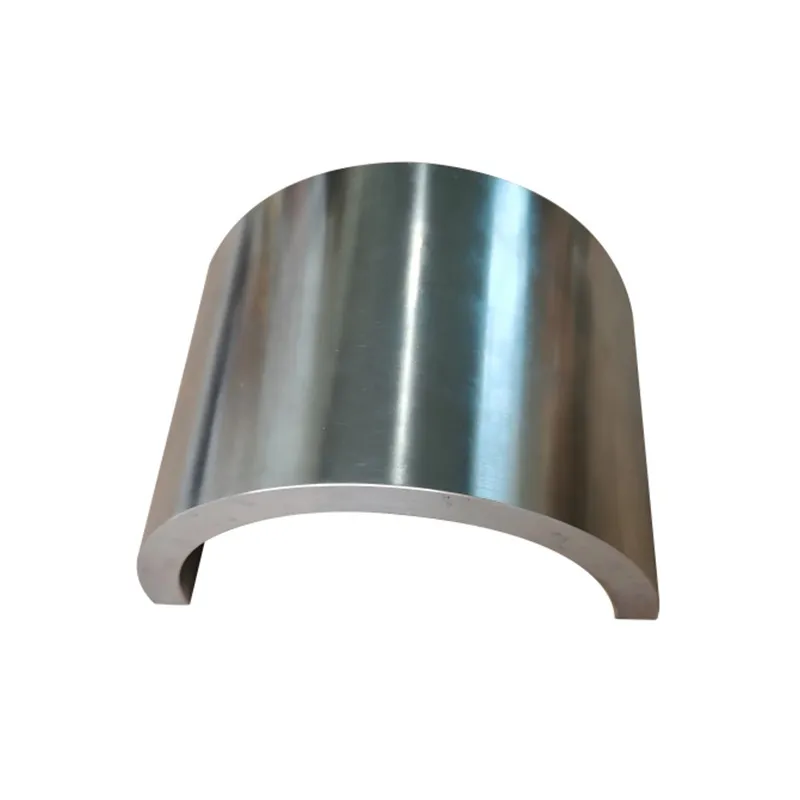

We manufacture professional, high-precision piston pump parts for a very well-known paint spraying equipment manufacturer in Europe. Due to the specific application environment, the parts are made from 304 stainless steel, and the dimensional accuracy requirements are extremely stringent.

Material Composition and Mechanical Properties Parameters:

1.4301/304 Stainless Steel Composition Table

| Chemical Composition |

| Elements |

C |

Ni |

Cr |

Mn |

Si |

P |

S |

N |

Fe |

| Percentage(%) |

≤ 0.08 |

8.0-10.5 |

18.0-20.0 |

≤ 2.0 |

≤ 1.0 |

≤ 0.045 |

≤ 0.03 |

≤ 0.10 |

Bal. |

2.Mechanical Properties

(1).Tensile Strength (T.S): ≥520 MPa

(2).Yield Strength (Y.S): ≥205 MPa

(3).Elongation (E.L): ≥40%

(4).Brinell Hardness (HB): ≤ 187

Manufacturing Process:

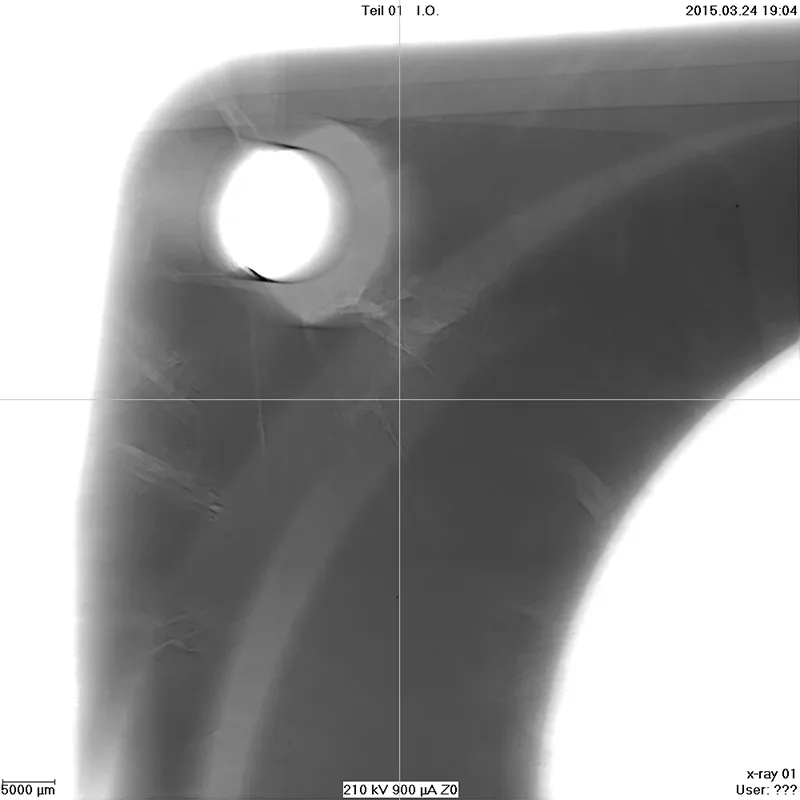

The parts are manufactured using the investment casting process. Investment casting is the most commonly used precision casting process for stainless steel materials, maximizing surface finish and ensuring casting accuracy. After casting, the parts undergo precision machining to meet the accuracy requirements of the assembly surfaces. After all casting and machining processes are complete, we perform coordinate measuring machine (CMM) inspection and X-ray internal flaw detection to ensure all dimensions and quality meet specifications.