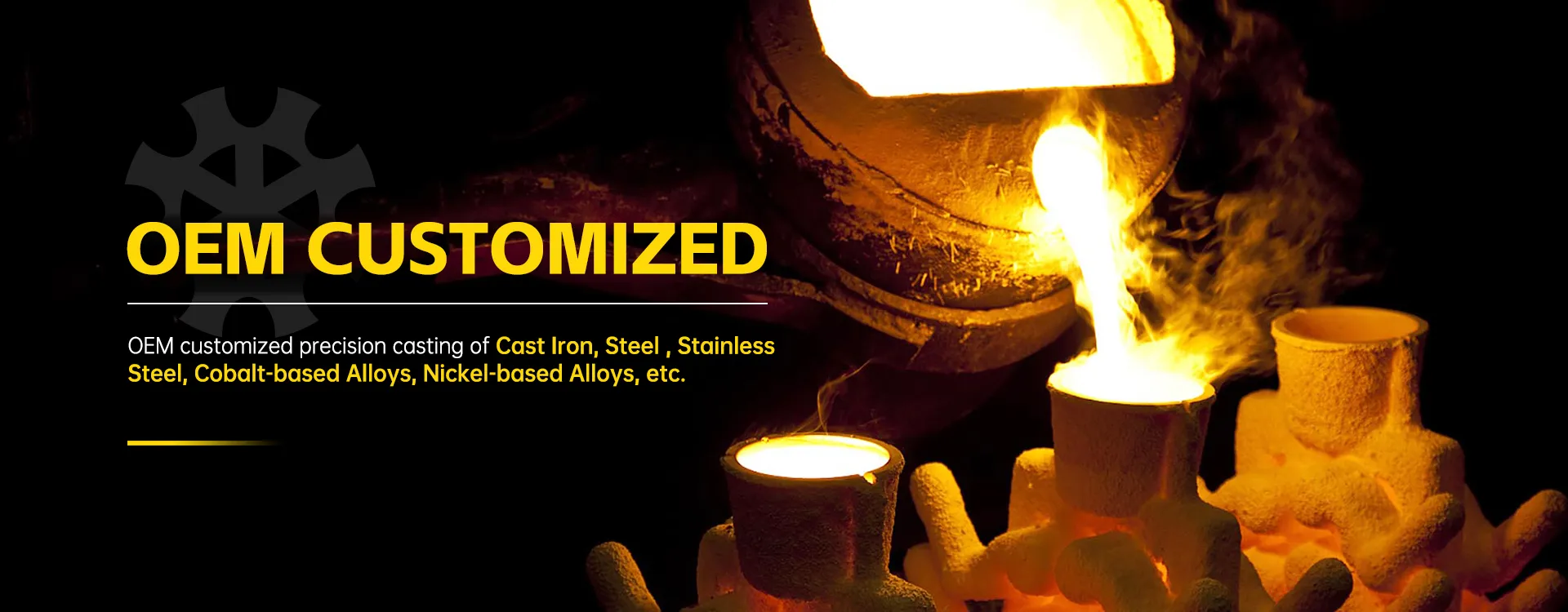

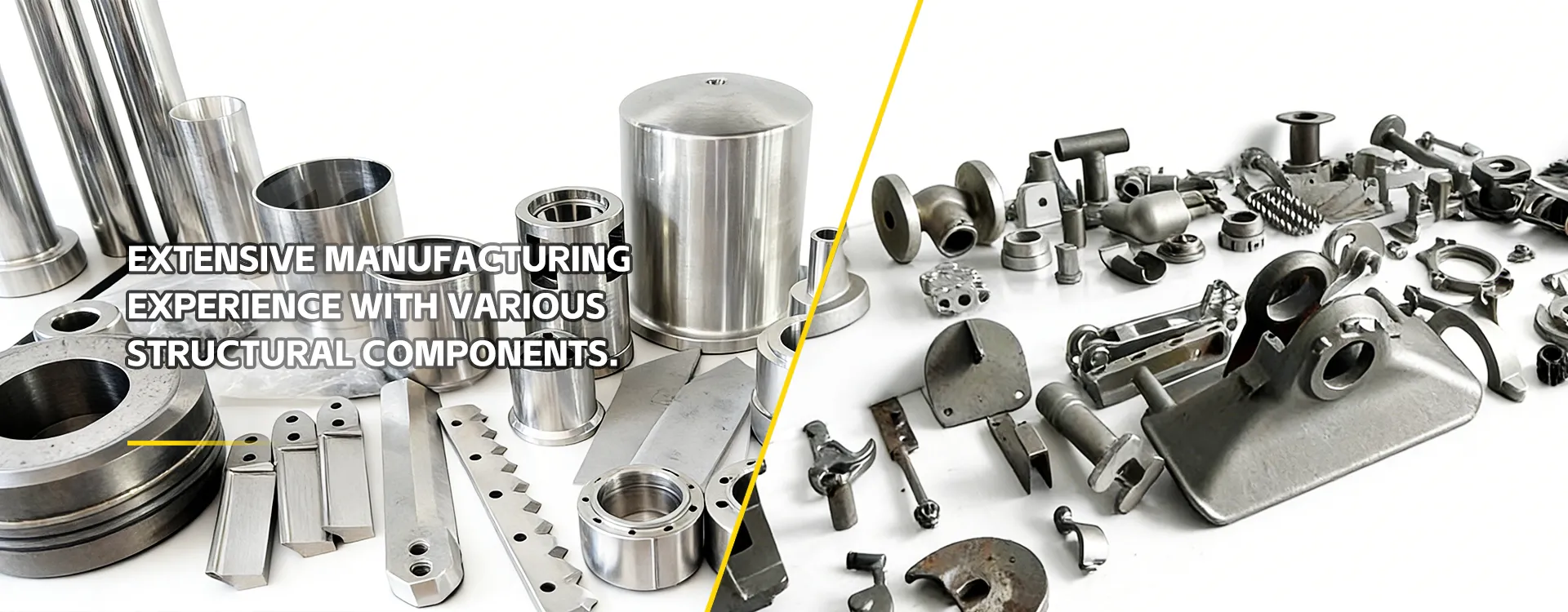

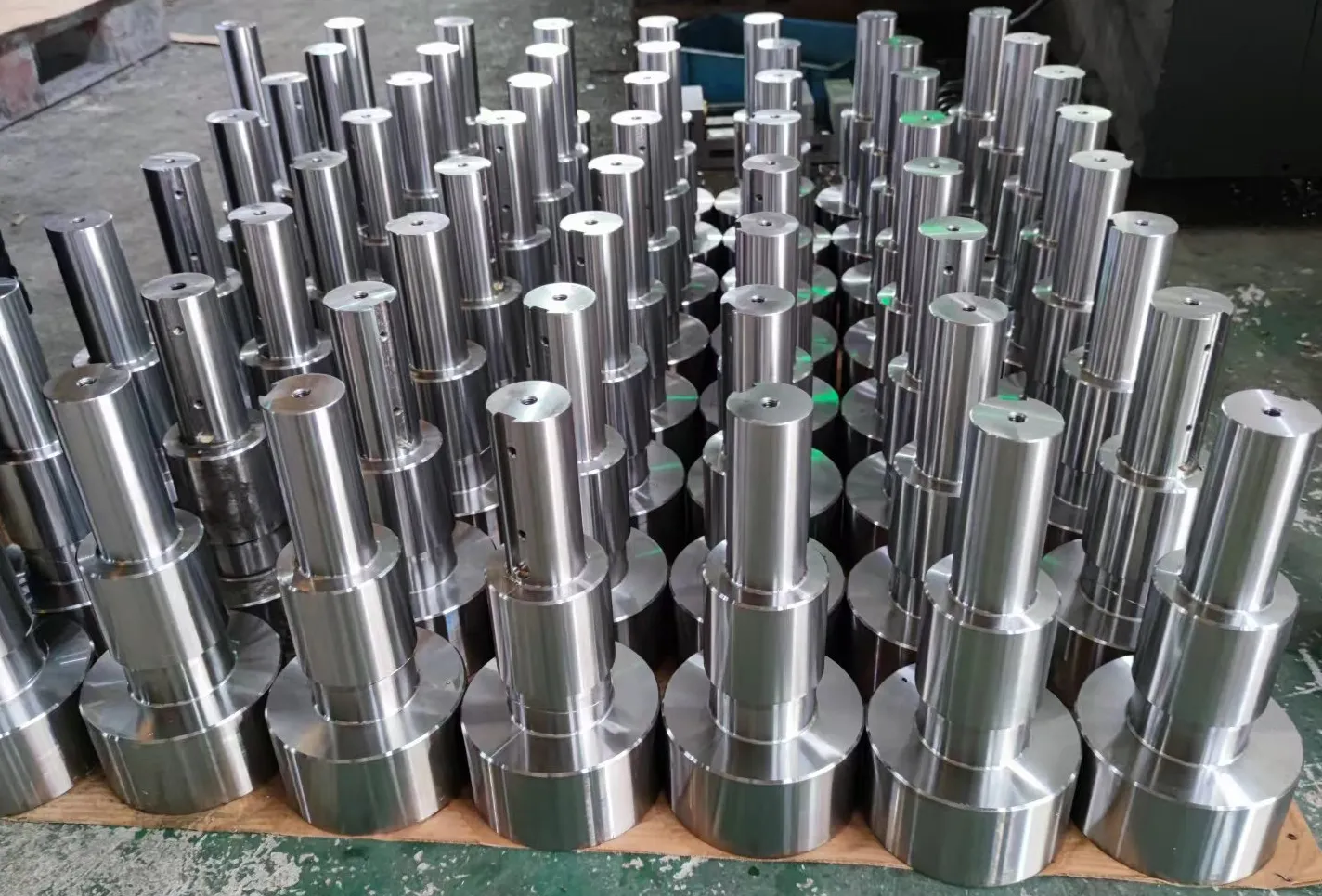

Utyalo-mali olulahlwayo (lost-wax casting) yinkqubo esebenzisa imodeli echanekileyo, elahlwayo eyenziwe ngemathiriyeli yewax efusible. Lo mzekelo ke uqatywe ngezaleko ezininzi zemathiriyeli ephikisayo ukwenza iqokobhe lokungunda elipheleleyo. Imodeli yewax iye yanyibilika ngokufudumeza, okukhokelela kwigobolondo le-ceramic lokungunda elingenanto eliphindaphinda ngokugqibeleleyo ubume bemodeli yewax yokuqala. Isinyithi esinyibilikisiweyo sigalelwa kwiqokobhe lokungunda, ekugqibeleni livelise intsimbi efana nemodeli yewax yokuqala. Le nkqubo yitekhnoloji engundoqo eyimfuneko kwimveliso ephezulu, ilungele ukuveliswa kwamacandelo abalulekileyo anemilo entsonkothileyo, izinto ezibizayo, kunye neemfuno zokusebenza ezibango. Ukusebenzisa le nkqubo, sinokuvelisa iindawo ezichanekileyo ezenziwe ngezinto ezahlukeneyo, kubandakanywa insimbi, insimbi engenasici, kunye ne-alloys ezikhethekileyo (ezifana ne-aluminium alloys, i-alloys-based alloys, kunye neentsimbi ezikhethekileyo ezingenasici, njl.).