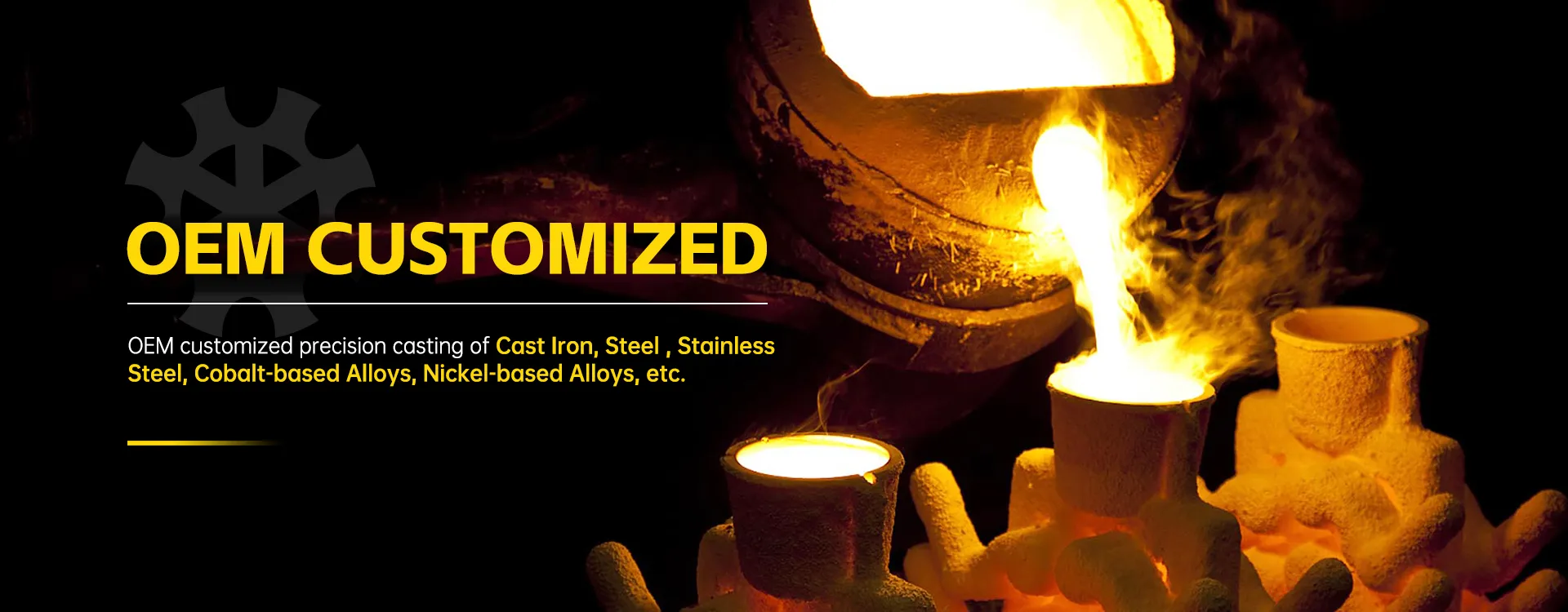

Ukufakwa kwe-investment casting(lost-wax casting) kuyinqubo esebenzisa imodeli enembile, elahlwayo eyenziwe ngezinto zengcina ezifusible. Lo modeli ube usumbozwa ngezendlalelo eziningi zezinto eziphikisayo ukuze kwakheke igobolondo lesikhunta eliphelele. Imodeli ye-wax ibe isincibilika ngokushisisa, okuholela egobolondweni lesikhunta se-ceramic esingenalutho esiphindaphinda kahle isimo semodeli yengcina yokuqala. Insimbi encibilikisiwe ibe isithelwa egobolondweni lesikhunta, ekugcineni ikhiqize ukubunjwa kwensimbi okufana nemodeli yengcina yokuqala. Le nqubo iwubuchwepheshe obuyisisekelo obubalulekile ekukhiqizeni okusezingeni eliphezulu, okufanele ikakhulukazi ukukhiqizwa kwezingxenye ezibucayi ezinobumo obuyinkimbinkimbi, izinto ezibizayo, nezimfuneko zokusebenza ezinzima. Ngokusebenzisa le nqubo, singakhiqiza izingxenye ezinembayo ezenziwe ngezinto ezihlukahlukene, okuhlanganisa insimbi, insimbi engagqwali, nama-alloys akhethekile (njengama-alloys e-aluminium, ama-alloys asekelwe ku-nickel, nezinsimbi ezikhethekile ezingenasici, njll.).