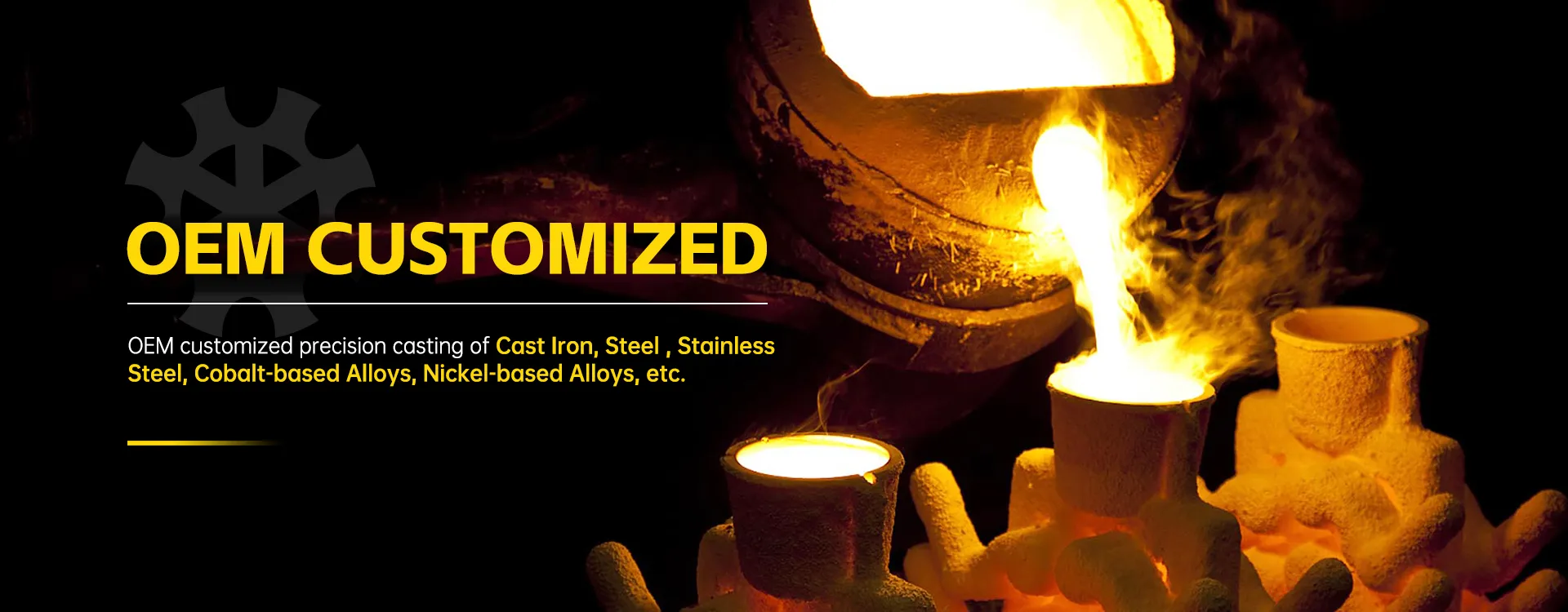

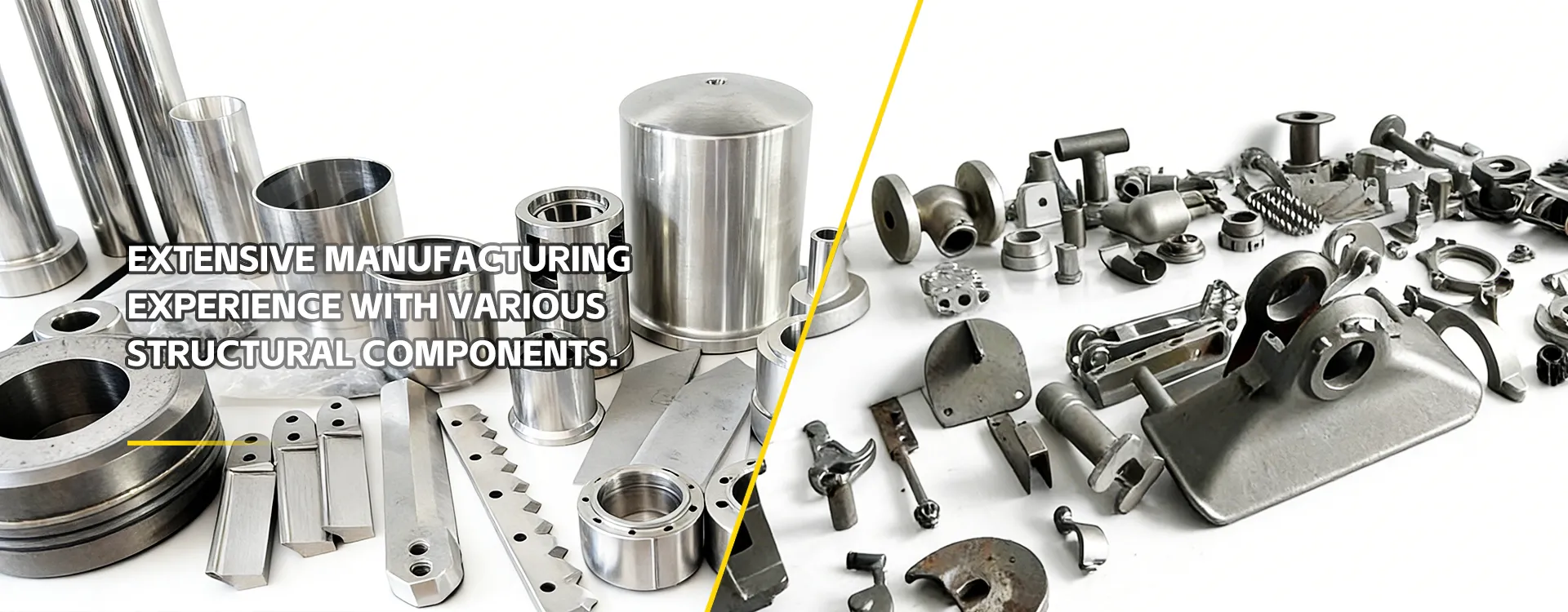

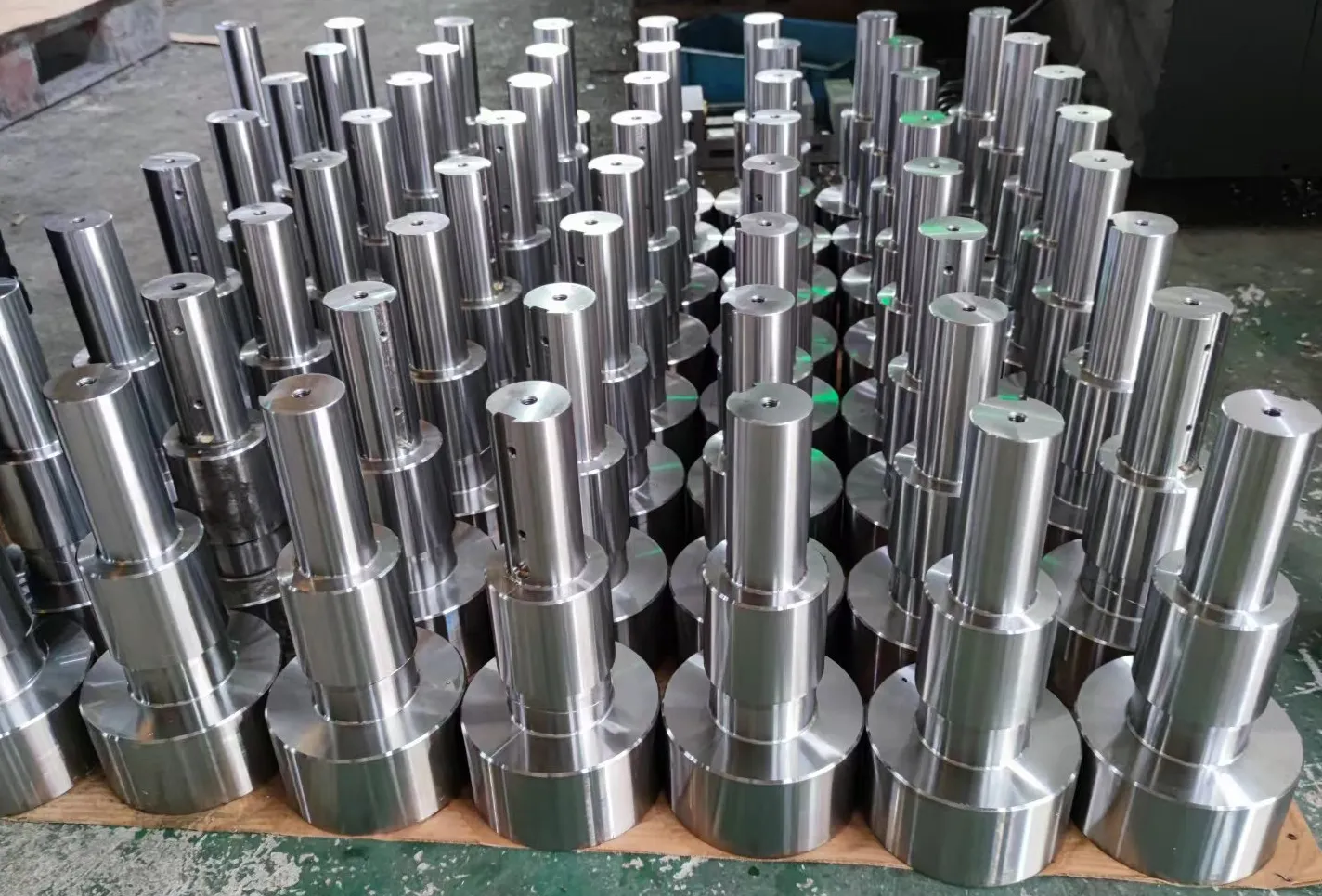

Investment casting(kutaya-wax casting) ndi njira yomwe imagwiritsa ntchito njira yolondola, yotayirapo yopangidwa ndi phula la fusible. Chitsanzochi chimakutidwa ndi zigawo zingapo za zinthu zokanira kuti apange chipolopolo chonse cha nkhungu. Sera imasungunuka ndi kutentha, zomwe zimapangitsa kuti pakhale chigoba chopanda kanthu chomwe chimafanana bwino ndi mawonekedwe a sera oyambirira. Chitsulo chosungunula chimathiridwa mu chigobacho, kenako n'kupanga chitsulo chofanana ndi phula loyambirira. Njirayi ndi ukadaulo wofunikira kwambiri pakupanga kwapamwamba kwambiri, makamaka koyenera kupanga zinthu zofunika kwambiri zokhala ndi mawonekedwe ovuta, zida zodula, komanso zofunikira pakugwirira ntchito. Pogwiritsa ntchito njirayi, tikhoza kupanga mbali zolondola zopangidwa ndi zipangizo zosiyanasiyana, kuphatikizapo zitsulo, zitsulo zosapanga dzimbiri, ndi ma alloys apadera (monga ma aloyi a aluminiyamu, alloys opangidwa ndi nickel, ndi zitsulo zapadera zosapanga dzimbiri, etc.).