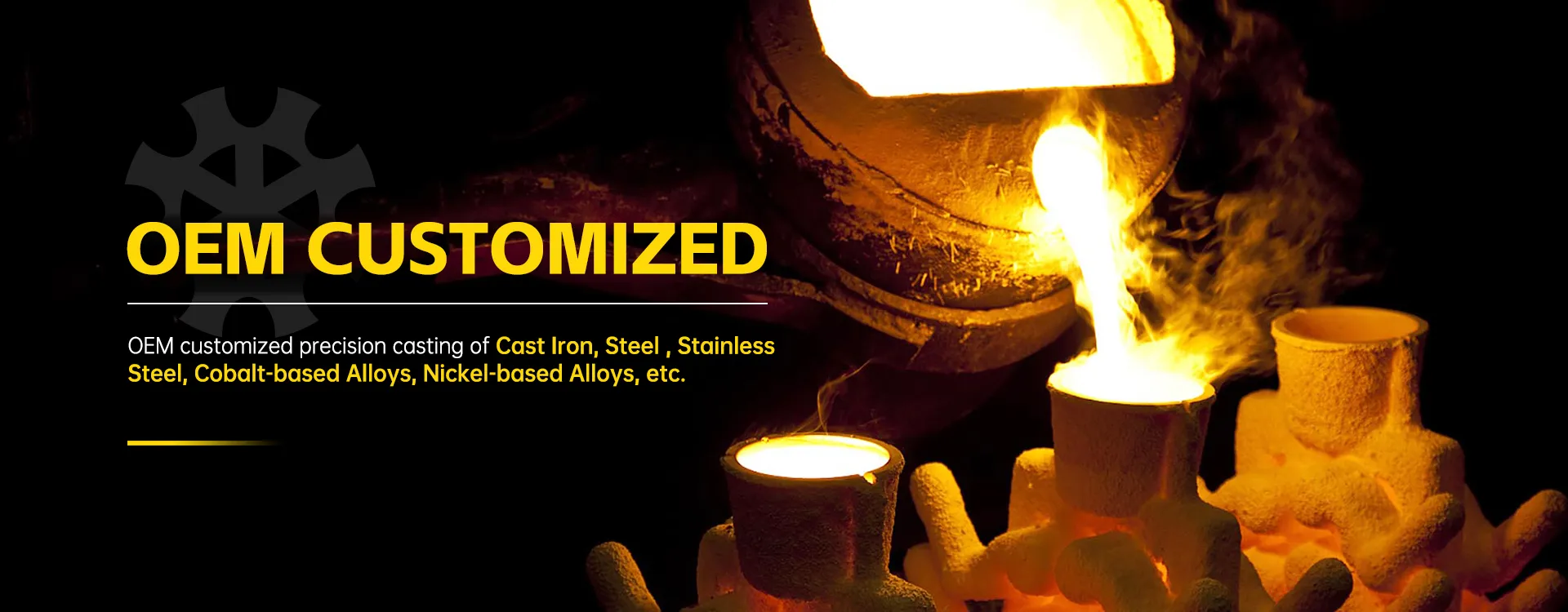

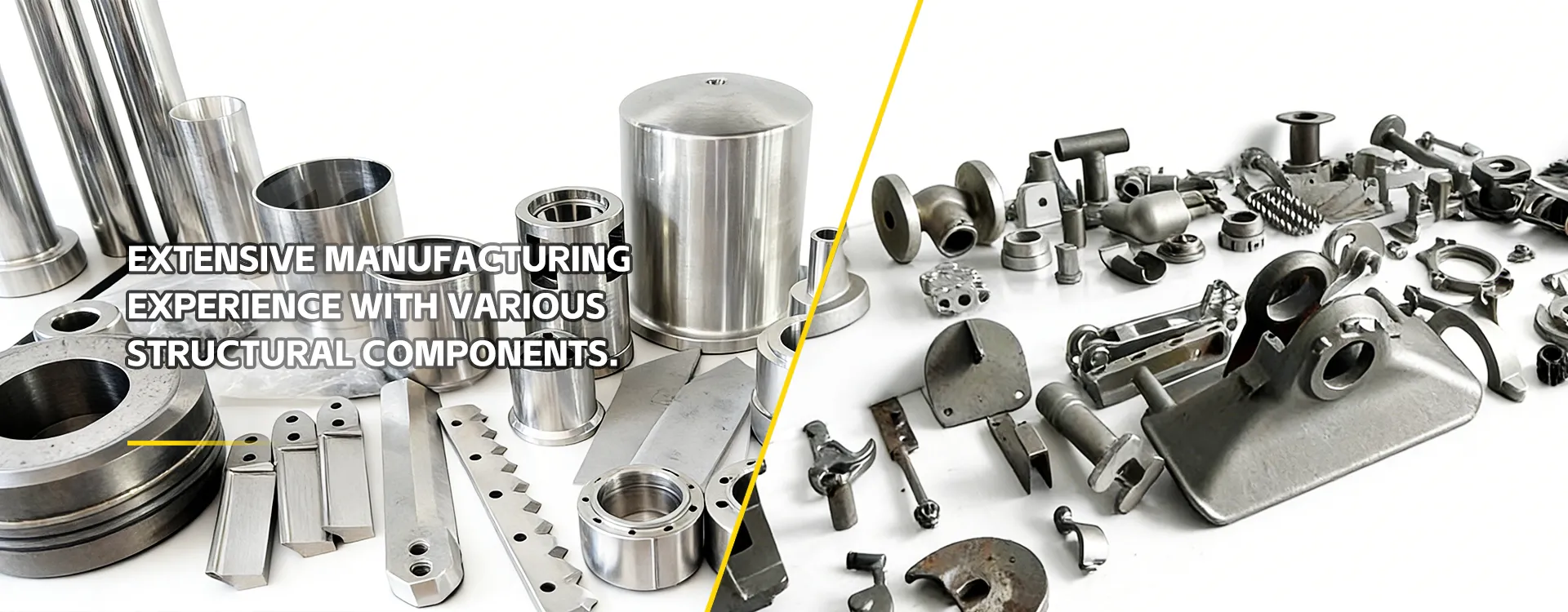

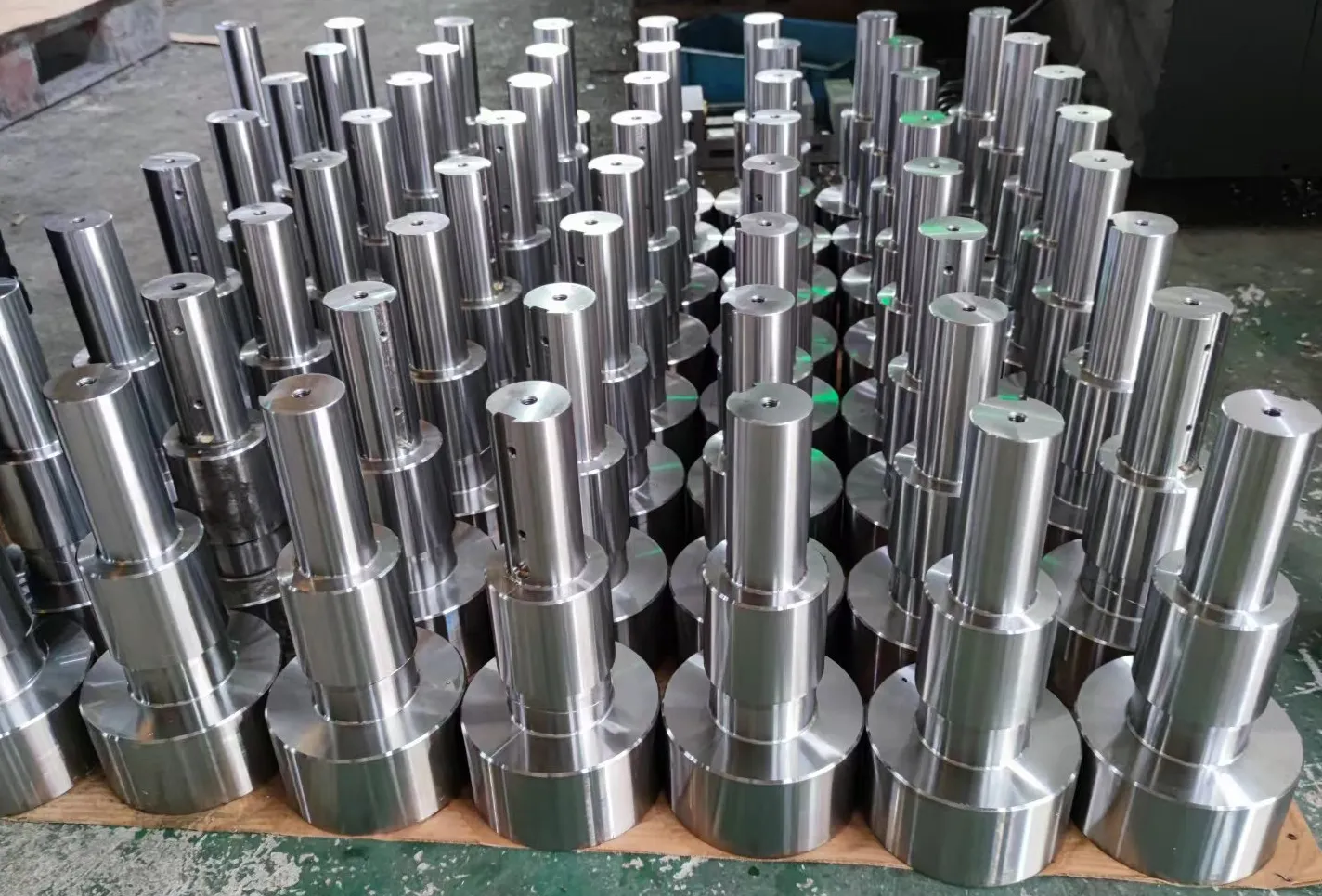

Investment casting(lost-wax casting) ke ts'ebetso e sebelisang mokhoa o nepahetseng, o lahloang o entsoeng ka thepa ea boka ba fusible. Joale mohlala ona o koahetsoe ka likarolo tse ngata tsa lintho tse refractory ho etsa khetla e feletseng ea hlobo. Joale mohlala oa boka o qhibilihisoa ka ho futhumatsa, e leng se etsang hore ho be le khetla e se nang letho ea hlobo ea ceramic e etsisang hantle sebopeho sa boka ba pele. Ka mor'a moo, tšepe e qhibilihisitsoeng e tšeloa ka har'a khetla ea hlobo, 'me qetellong e be e entsoeng ka tšepe e tšoanang le ea boka ba pele. Ts'ebetso ena ke theknoloji ea mantlha ea mantlha indastering ea maemo a holimo, haholo-holo e loketseng tlhahiso ea likarolo tsa bohlokoa tse nang le libopeho tse rarahaneng, thepa e theko e boima, le litlhoko tse boima tsa ts'ebetso. Ha re sebelisa ts'ebetso ena, re ka hlahisa likarolo tse nepahetseng tse entsoeng ka thepa e sa tšoaneng, ho akarelletsa le tšepe, tšepe e sa hloekang, le li-alloys tse khethehileng (tse kang li-alloys tsa aluminium, li-alloys tse thehiloeng ho nickel, le litšepe tse khethehileng tse sa hloekang, joalo-joalo).